When it comes to providing optimal ventilation in large environments such as livestock facilities, greenhouses, and industrial spaces, selecting the right fan drive is crucial. Two popular options in the market are direct drive and belt drive fans. In this article, we will explore the differences between these two types of fans, helping you make an informed decision for your specific application.

Belt Drive Fans:

Belt drive fans have been a traditional choice for large industrial applications. They consist of an electrical motor connected to the fan blades through a belt and pulleys. While they may have more components, belt drive fans offer unique advantages for specific environments.

Advantages of Belt Drive Fans:

- Flexible configuration: Belt drive systems allow an easy adjustment of fan propeller speed by changing the pulley size. This flexibility is beneficial when it is necessary to change the configuration of the fan from one motor size to another or from 50Hz to 60Hz power supply.

- Lower Initial Cost: Belt drive fans have a lower upfront cost if compared to direct drive fans. This can be a deciding factor for budget-conscious buyers.

- Easy Motor Replacement: If the motor fails in a belt drive system, it can be easily replaced without dismounting a lot of parts. This can result in cost savings during maintenance.

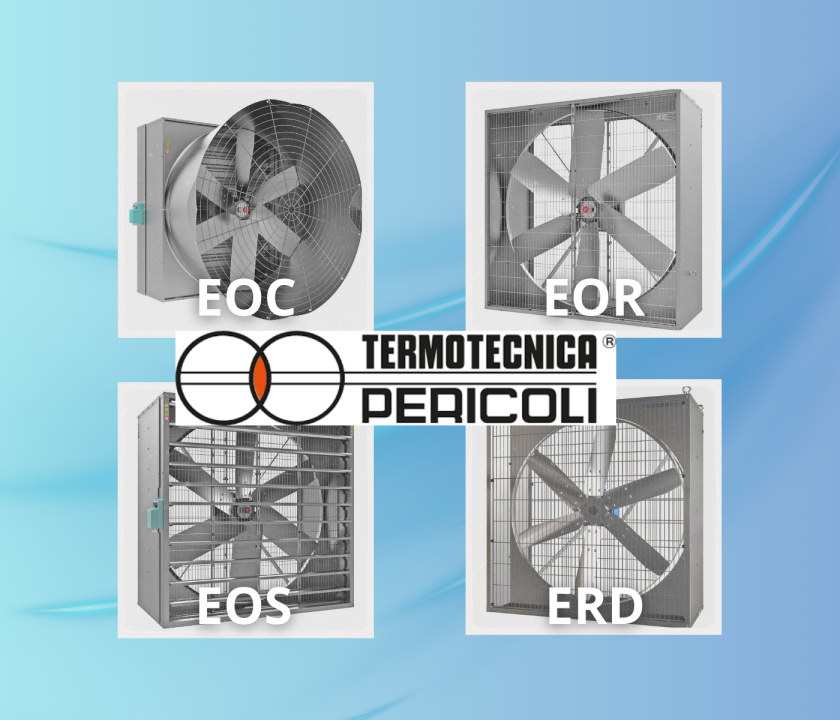

Termotecnica Pericoli includes among its best sellers EOS and EWS, but also the cone fan EOC and the circulator EOR, all belt-driven fans.

Direct Drive Fans:

Direct drive fans have gained popularity in recent years due to their simplicity and efficiency. These fans have the impeller directly connected to the motor, eliminating the need for a belt and pulleys system. This direct coupling enhances energy efficiency and reduces maintenance requirements.

Advantages of Direct Drive Fans:

- Energy Efficiency: Direct drive fans have higher energy efficiency typically since there is no energy loss through the belt and pulleys system. This can result in lower operating costs over time.

- Lower Maintenance: With fewer components, direct drive fans require less maintenance generally. There is no belt to tension or replace, reducing downtime and associated maintenance costs. The reduced requirement of maintenance makes the direct drive option ideal for all those applications where the accessibility to the equipment is difficult or limited.

’Discover all our direct-driven models such as EWD, ERD, EOC DS or the G-line

Discover all our models

Conclusion:

In conclusion, the choice between direct drive and belt drive fans for large environments depends on specific application requirements and, budget considerations. Direct drive fans are energy-efficient and low-maintenance, while belt drive fans offer simplicity and cost advantages. Consider your unique needs and consult with ventilation experts to determine the most suitable fan drive for your large environment.

Direct drive fans are recommended to be used in all those applications where due to biosecurity restrictions or the inconveniency of the equipment set-up, the maintenance process is limited to the minimum. In all these cases (layer farms, breeder farms, special industrial applications, etc.), the direct drive fans can give peace of mind to the user.

Belt-driven fans are the ideal solution for users who are looking for simplicity at a competitive price. In particular, in all those areas where spare parts or skilled workers are not easy to find, the usage of a simple equipment is recommended.

For more information visit: https://www.pericoli.com/