TERMOTECNICA PERICOLI, A HISTORIC ITALIAN COMPANY, PRODUCES BOTH PAPER AND PVC PANELS

In the world of agriculture, maintaining optimal environmental conditions is crucial for the health and productivity of livestock and horticultural crops.

- When it comes to cooling systems, the choice between cellulose and plastic cooling pads can significantly impact the overall efficiency and success of the operation.

In this article, we will delve into the differences between cellulose and plastic cooling pads and their respective advantages and disadvantages in the realm of livestock and horticulture.

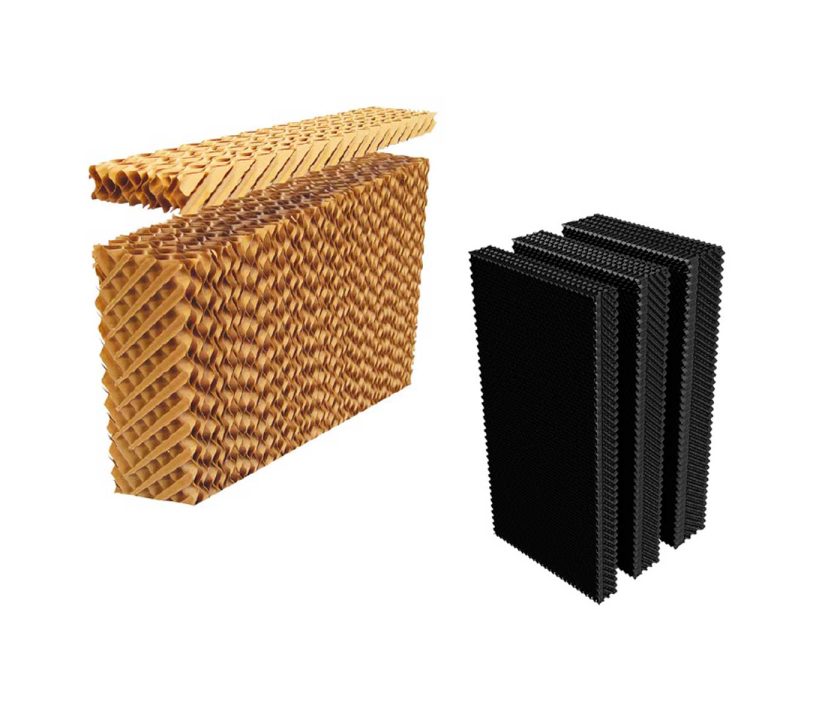

PAPER COOLING PADS

Cellulose cooling pads, also known as evaporative cooling pads, are crafted from a natural, organic material – cellulose paper.

These pads are designed to absorb and retain water, promoting the cooling process through evaporation.

- The effectiveness of cellulose cooling pads lies in their ability to provide a consistent and efficient cooling effect, especially in hot and dry climates.

ADVANTAGES OF CELLULOSE COOLING PADS

- High Evaporative Efficiency: Cellulose pads excel in evaporative cooling, making them highly effective in reducing temperatures in livestock and horticultural environments.

- Cost-Effective: Cellulose cooling pads are often more cost-effective in the long run compared to plastic counterparts, considering their efficiency and durability.

- Low Energy Consumption: These pads typically require low energy to operate, contributing to lower overall operational costs.

DISADVANTAGES OF CELLULOSE COOLING PADS

- Maintenance Requirements: Cellulose pads may require more frequent maintenance and replacement due to the organic material’s susceptibility to wear and tear.

- Vulnerability to Algae Growth: In humid conditions, cellulose pads may be prone to algae growth, necessitating additional cleaning and maintenance efforts. Despite this apparent disadvantage, Termotecnica Pericoli offers customers paper cooling pads with an anti-algae treatment to overcome this problem.

PLASTIC COOLING PADS

Plastic cooling pads are constructed from durable materials like PVC. Unlike cellulose pads, plastic pads rely on a different mechanism for cooling, utilizing a wet wall system to reduce temperatures.

See Plascool product sheet here

ADVANTAGES OF PLASTIC COOLING PADS

- Durability: Plastic cooling pads are resistant to wear and tear, making them a durable option for long-term use.

- Low Maintenance: These pads are less susceptible to algae growth and require less frequent maintenance compared to cellulose pads.

- Suitable for Humid Conditions: Plastic cooling pads perform well in humid climates, where cellulose pads might face challenges.

- Long Lifespan: Due to their robust construction, plastic cooling pads generally have a longer lifespan, reducing the frequency of replacements.

- Low pressure drops: at the same crossing speed plastic panels are characterized by a lower pressure loss.

DISADVANTAGES OF PLASTIC COOLING PADS

- Higher Initial Cost: Plastic cooling pads may have a higher upfront cost compared to cellulose pads.

The choice between cellulose and plastic cooling pads ultimately depends on the specific needs and conditions of the livestock or horticultural operation.

While cellulose pads are celebrated for their efficiency in dry climates, plastic pads shine in durability and suitability for humid environments.

Understanding the advantages and disadvantages of each type allows farmers and growers to make informed decisions, tailoring their cooling systems to optimize productivity while considering long-term sustainability and cost-effectiveness.

Termotecnica Pericoli offers its customers both solutions, effectively being able to choose between Pericool and Plascool. High performance evaporative panels produced in Italy in our fully automated Pericool Division.

PDF