Discussing changes in consumer purchasing trends in the egg sector sounds redundant. The great efforts made by the producers to adapt to new and varied demands are already evident. And all this in record time, with no effective interval for the recovery of the amortizations of those investments that the sector had to undertake until 2012.

- These new systems, their management, the adjustment of the birds to them, as well as the new sanitary and nutritional needs required, are by now well known to poultry farmers. However, it is necessary to carry out a scrupulous revision of their costs (if it has not already been done), adapted to each production volume, to the idiosyncrasies of each production farm.

Obviously, the cost analysis scheme does not vary with respect to previous scenarios in which we mostly produced eggs in enriched cage systems.

This article aims to carry out this study in a general way, taking into account each cost and its percentage variation with respect to the costs in similar conditions for code 3 productions. It is important to note that all costs and data considered refer to eggs produced on egg belts, without any packing and grading costs in the packing center and no distribution costs.

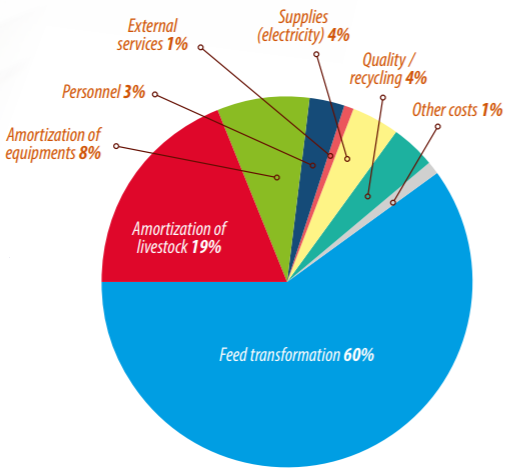

In any egg production system, the main costs are summarized in:

- Feed transformation

- Amortization of livestock

- Amortization of equipments

- Personnel

- External services

- Supplies (electricity)

- Quality costs (declassified egg)

- Other costs (health requirements, insurance …)

As we can see in the attached graph, the first four entries in the list above make up 90% of the total costs, so, although we will be reviewing all of them, we must first focus on analyzing the big four.

Cost distribution in enriched cages

As mentioned at the beginning, all the data of this cost study will be expressed as a percentage of cost variation always in relation to the production of eggs in enriched cages. This is due to the logical impossibility of carrying out an economic study that considers all the specific conditions of each company, as well as the heterogeneity of the size and the productive structure of the different farms (floor, free-range and organic eggs), since in some cases they are part of a project to be completed in the coming years.

EGG PRODUCTION

Before reviewing each of the main cost lines, we must set the divisor of all the items that make them up in relation to the number of eggs per housed hen in enriched cages, floor production and free-range egg systems.

The ecological system will not be studied due to its low incidence still in our country with respect to the other three productions, although we are aware that in future revisions it will be necessary to include it if the percentage in the number of farms follows an increase, similar to the one experienced in the last five years.

Another determining factor of the study is the inclusion of brown, and not white egg strains, due to how representative each one is in the Spanish market.

For this study we have considered the following total production data for 80 weeks of life *:

- Cage systems: 30.4 dozen per housed hen

- Floor systems: 30.0 dozen per housed hen

- Free-range production: 29.4 dozen per housed hen

* The 80 weeks of life has been taken as a reference, since in cages it is an already achieved target and it is already beginning to be achieved in alternative systems.

As it can be clearly seen, there are hardly any productive differences between the cage system and the floor system, although in the case of the free-range, the difference is significant.

FEED TRANSFORMATION

Regarding the price of feed, we must emphasize that the nutritional strategy in floor and free-range systems is somewhat different from the cage system, fundamentally in how we distribute them to the birds, but without significant differences in terms of its nutritional content.

That is why the variations between the different systems come from the daily consumption of feed in each production system. It is important to consider that we often provide feed in crumbs in alternative systems, which comes with an extra cost of around 4 ,5% due to the technological process it requires.

Keep up to date with our newsletters

Receive the magazine for free in digital version

REGISTRATION

ACCESS

YOUR ACCOUNT

LOGIN

Lost your password?