Content available at: Español (Spanish) العربية (Arabic)

Veterinarians and professionals who work in animal production have traditionally been trained to isolate or detect the etiologic agents causing the clinical symptoms reported in poultry facilities.

Identification is often achieved by replicating the clinical picture of the disease or intoxication observed in animals.

In the case of toxins, some feed mills often maintain experimental poultry houses, where they can test whether a nutritional ingredient or contaminant is causing the reported intoxication.

-

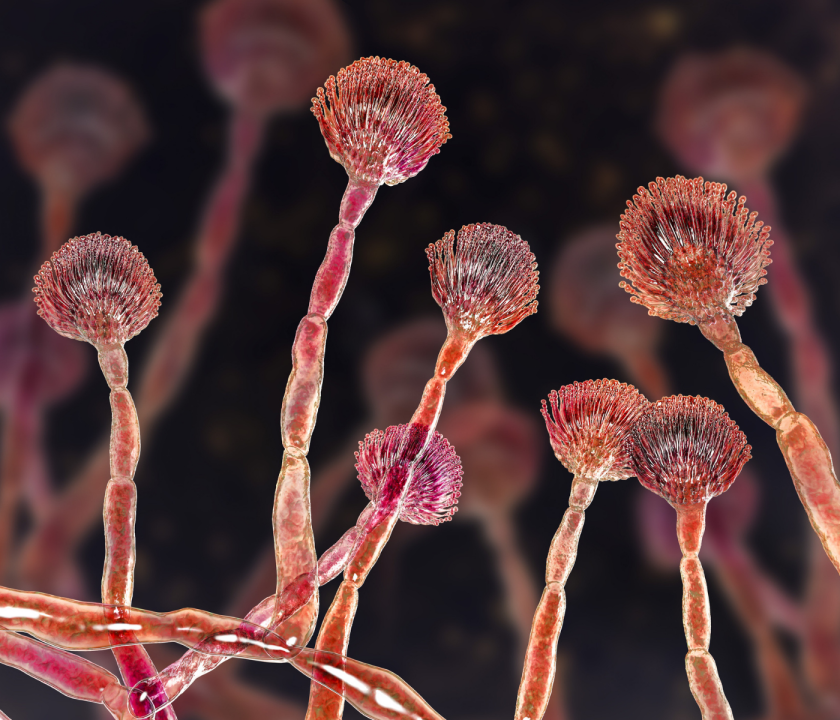

Despite the fact that mycotoxins are not living microorganisms, but rather metabolites produced by fungi as they grow, we tend to try to conclusively detect which is the etiological agent.

-

In other words, demonstrate that the mycotoxins were present in the feed consumed by the affected animals.

Unfortunately, it is not always possible to identify the mycotoxins that caused different symptoms or lesions in the animals after seeing a case that we consider typical.

Below, we list the causes that prevent us from being able to confirm the relationship between what we see in the field and the presence of mycotoxins in the analysis:

- Irregular distribution of mycotoxins in grains and feed.

- Sampling errors.

- Laboratory techniques used to do the analysis.

- Presence of conjugated or masked mycotoxins.

IRREGULAR DISTRIBUTION OF MYCOTOXINS

Unlike the protein or moisture content in corn or soybeans, mycotoxins are not uniformly distributed. The main reason is that fungi do not grow everywhere, they do so in specific places.

>> This trend can start in the field.

>> Some grains can contain high levels of mycotoxins while others do not.

>> At the level of feed mills, especially in silos, fungi grow mostly where humidity is more prevalent, also known as “hot spots”.

-

These points have been identified for decades and occur due to the mobilization of moisture from the outside to the inside of the silo or storage area, mostly at night when ambient temperatures drop.

- The changes in temperature produce condensation on the internal walls of the silo, which promote the growth of fungi.

>> The same phenomenon can occur in trucks, barges and other compartments where grain or feed are stored.

SAMPLING

A correct analysis means detecting the average contamination within a batch of grain or finished feed. If proper sampling procedures are not followed, analytical results are likely to underestimate the true mycotoxins concentration.

-

That is, if only areas with low or without contamination are sampled, no actual results will be obtained.

-

False negative results can occur as a result of inadequate sampling and poor preparation of the sample tested.

-

When few incremental samples are taken or the total batch sample is too small, it is common to “lose” a contaminated grain than to “find” it.

The chances of identifying mycotoxins in feed increase if they are taken from feeders located on farms, because that feed has been stored inside the silos for about 5 to 7 days and close to a day inside the house, once it is transferred to the hoppers and then to the feeders (automatic feeders).

The time that the feed remains in the farms depends on the company’s management and the type of birds raised.

Unfortunately, even in clinical cases of mycotoxicosis where affected animals show typical lesions and where samples are taken following the correct methodology, we often fail to identify them.

Keep up to date with our newsletters

Receive the magazine for free in digital version

REGISTRATION

ACCESS

YOUR ACCOUNT

LOGIN

Lost your password?