When it comes to providing optimal ventilation in large environments such as livestock facilities, greenhouses, and industrial spaces, selecting the right fan drive is crucial. Two popular options in the market are direct drive and belt drive fans. In this article, we will explore the differences between these two types of fans, helping you make an informed decision for your specific application.

Belt drive fans have been a traditional choice for large industrial applications. They consist of an electrical motor connected to the fan blades through a belt and pulleys. While they may have more components, belt drive fans offer unique advantages for specific environments.

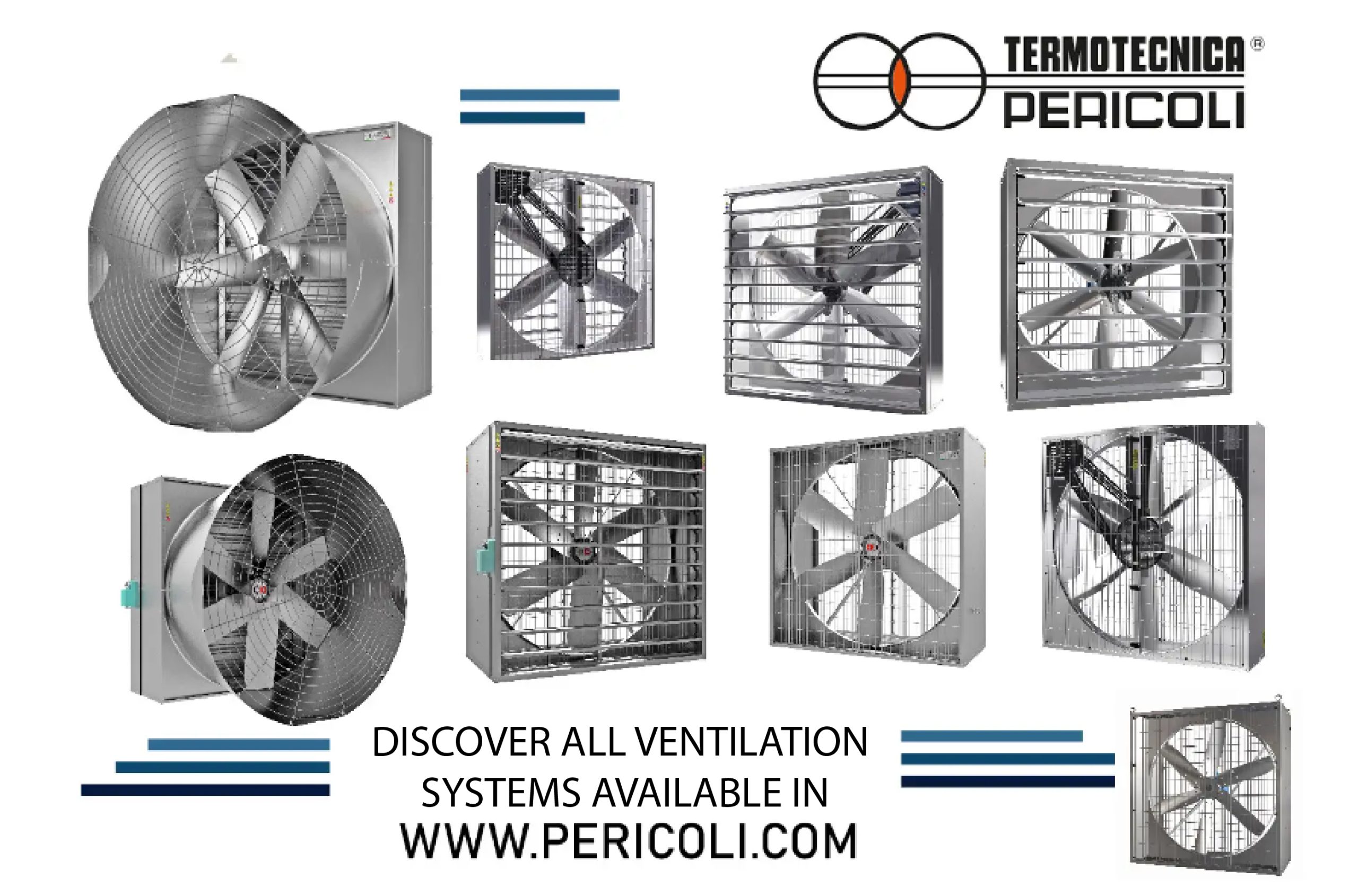

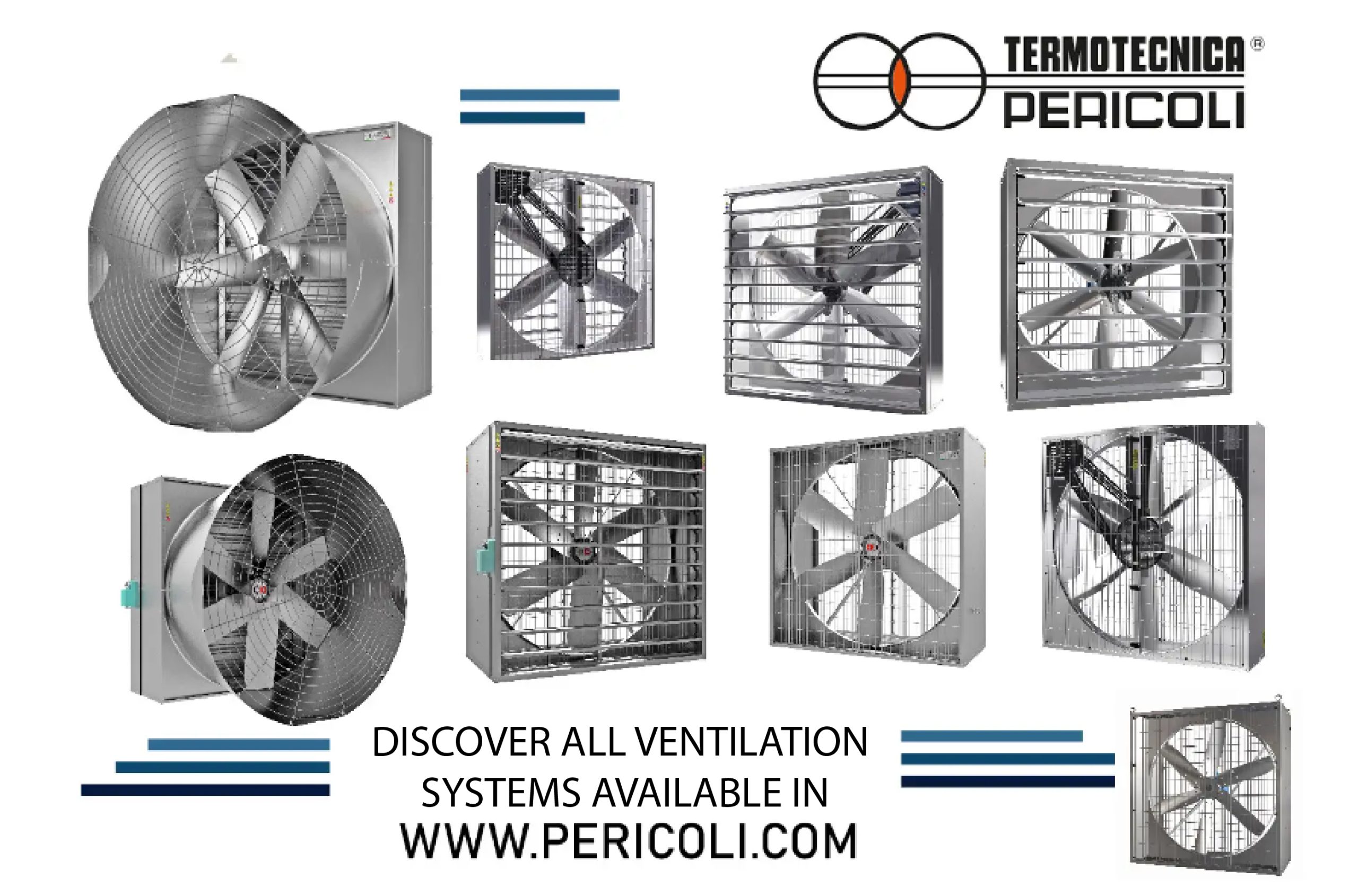

Termotecnica Pericoli includes among its best sellers EOS and EWS, but also the cone fan EOC and the circulator EOR, all belt-driven fans.

Direct drive fans have gained popularity in recent years due to their simplicity and efficiency. These fans have the impeller directly connected to the motor, eliminating the need for a belt and pulleys system. This direct coupling enhances energy efficiency and reduces maintenance requirements.

’Discover all our direct-driven models such as EWD, ERD, EOC DS or the G-line

Discover all our models

In conclusion, the choice between direct drive and belt drive fans for large environments depends on specific application requirements and, budget considerations. Direct drive fans are energy-efficient and low-maintenance, while belt drive fans offer simplicity and cost advantages. Consider your unique needs and consult with ventilation experts to determine the most suitable fan drive for your large environment.

Direct drive fans are recommended to be used in all those applications where due to biosecurity restrictions or the inconveniency of the equipment set-up, the maintenance process is limited to the minimum. In all these cases (layer farms, breeder farms, special industrial applications, etc.), the direct drive fans can give peace of mind to the user.

Belt-driven fans are the ideal solution for users who are looking for simplicity at a competitive price. In particular, in all those areas where spare parts or skilled workers are not easy to find, the usage of a simple equipment is recommended.

For more information visit: https://www.pericoli.com/

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón