Chicken manure extraction is carried out using polypropylene tapes and with a frequency of 3 to 7 days, depending on the length of the shed. Until now, chicken manure was transported abroad where trucks collected it. The humidity percentage of the chicken manure ranged between 80% and 85%.

ZUCAMI has developed a treatment system that dries 85% of the chicken manure and eliminates odors, insects and gases derived from ammonia: the Seconov system.

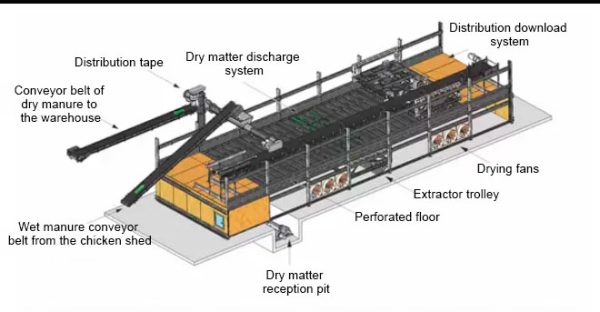

Once extracted, the manure is transported to the upper part of the Seconov where a mechanical rake spreads it forming a thin layer. Through a tunnel that communicates with the shed and through powerful fans, the system uses the heat generated by the birds themselves to dry the layer of chicken manure. Once dry, it is dropped to the bottom of the tunnel from where it will be transferred to the warehouse. With this system, the poultry farmer can preserve the chicken manure until it is marketed.

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón