Content available at: Indonesia (Indonesian) Melayu (Malay) ไทย (Thai) Tiếng Việt (Vietnamese) Philipino

Cleaning and Disinfection of Open Sided Houses and Humid Season Broiler Production

OVERVIEW

Hello poultry farmer, the rainy season is upon us!

In Zimbabwe and most Sub-Saharan countries with similar climate seasons, most small-scale poultry farmers struggle during the rainy season, with challenges of effectively managing a broiler production batch when humidity levels are high, and this promotes bacterial infections. Slow growth rate and stunted growth is seemingly the order of the season for most small-scale poultry farmers and some large-scale farmers. Around this season, I am often faced with one question in particular from many farmers,

“Why are my birds not growing”?

- In the case of the Zimbabwean poultry community, this trend has brought about a widespread belief amongst small scale farmers that chick and feed suppliers do not value quality as they aim to push volumes for the Christmas market rush.

- However, there is also one common factor that is always often overlooked, which affects farmers around this time, Humidity!

Towards the festive season, placement of broiler batches almost always clashes with the beginning of the rainy season. Bear in mind, this is also the season almost every farmer is trying to maximize returns from batches and produce a broiler batch that will be just ready in time for the Christmas market by doing multiple batches at a time.

The result is often linked with taking short cuts on critical activities such as cleaning and disinfection and cutting down the fowl run/site downtime resting period, then production problems arise, these factors are often overlooked.

- This trend has resulted in some poultry farmers in Zimbabwe resorting to taking production breaks during the rainy season, with the fear of the challenges they encounter yearly around this time, such as high mortalities, slow growth rate and stunted growth.

- However, this is not efficient, and it reduces the farmer’s annual returns.

It is therefore important to look at the main factor that is often overlooked to achieving success through this season. Understanding the major root of the problem for broiler farmers during the rainy season is an essential step towards achieving a solution that enables farmers to produce all year round, without seasonal breaks and with limited challenges.

- The beginning of a broiler production cycle starts with the end of the previous batch.

- The success of the next batch is dependent on how well the cleanout is done for the previous batch.

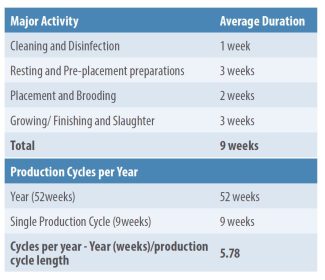

- In Zimbabwe commercial small scale and large-scale farmers aim to produce broiler batches on a 9- week cycle, all things being equal. This means they will place a batch every 9 weeks.

9-week Broiler Production Cycle

To be profitable, broiler farmers need to consider religiously following the standard cycle to attain maximum possible annual returns while observing best practice. The figure below provides details on the cycles per year a broiler farmer can do, in the Zimbabwean context.

Broiler production cycles per year (9-week cycle)

When a farmer skips a batch, this negatively impacts their annual returns. Therefore, it is imperative to consider how farmers can maximize during this time by overcoming challenges to remain efficient.

Majority of small-scale farmers rely on the use of open-sided housing systems and to be efficient, farmers need to invest more effort into best practice to be competitive all year round.

Small-scale farmers with open-sided housing systems, use either earth floors or concrete floors, with majority of small-scale poultry farmers using earth floors.

- As highlighted earlier, the stage of cleaning and disinfection is critical in the broiler production cycle.

- This is the beginning of the broiler cycle, and it is important to do this stage well as it sets the performance bar for the coming batch.

- There should be no visible evidence of a previous flock on site.

- Additionally, manure should be disposed carefully with caution to avoid contamination of the site by downwind influence of the old flocks’ manure.

General Guidelines for Cleaning and Disinfection of Concrete and Earth/Dirt Floors in an Open-Sided Housing System

Cleaning and disinfection for earth floors and concrete floors differ in the cleaning process, it is important to follow the cleaning guidelines for the type of floor onsite in order to achieve the best results in the next batch. Below are some general detailed steps that can help poultry farmers to clean and disinfect well and avoid challenges, that become more pronounced when the rainy season begins, and the humidity levels rise.

Stage 1 – Dry Cleaning

A. Removal of manure should generally begin on the day the last birds are depleted, and the aim for the farmer should be to complete this within 2 days.

B. Manure should be disposed of as far as possible from the fowl run, at least 500 m away from the site (in the case of small holder farmers with limited land space) or more, on the leeward side or composted. Some poultry farmers, use the grass for bedding and they retain the manure for their cattle, or they sell to cattle farmers. It is always important to stick to timelines, to avoid disturbing the production cycle timelines. For farmers that process their chicken manure for cattle feeding, these general guidelines below can be followed:

-

- The manure should be turned and dried in the house for two days starting from the day the last birds go to the market.

- On day 3 manure should be bagged and removed from the house, stored in a clean shade away from the fowl run awaiting collection the following day.

- Cleaning of the house should start on the 4th day.

- These timelines are critical to ensure adequate resting period before the next placement.

C. The roof, poles and fence should be cleaned by dusting removing all the cobwebs.

D. Thorough scrapping and sweeping should be done before the wet cleaning stage to make it easy to remove the compacted bedding remains on the floor, and to avoid further pasting onto the floor when water is poured.

Earth floors

- The topsoil should be scrapped off.

- All debris should be swept, with no trace of manure remaining.

Concrete floors

- All the debris on the floor should be swept with no trace of manure remaining.

E. Any repairs and maintenance work should also be done timely during the dry-cleaning stage.

Stage 2 – Wet Cleaning

F. Plain clean water should be used to remove loose residual manure and dust from the whole house including the roof (often forgotten or overlooked by farmers).

G. The poles, walls, roof, wire mash should all be thoroughly scrubbed with clean plain water first.

H. Equipment (manual feeders and drinkers) and curtains should be removed and cleaned/washed with clean plain water first.

Stage 3 – Chemical Cleaning

I. Once all the above steps have been thoroughly done, chemical cleaning can then begin followed by the disinfection process.

J. Equipment, curtains, poles, walls, roof and wire mash should be washed for the second time with a detergent by thoroughly scrubbing and allowing for recommended contact time before rinsing off with water thoroughly.

K. Before application of disinfectant, the house should be left to dry, this is done to avoid further dilution of the disinfectant by the residual water which can weaken the strength of the disinfectant (a disinfectant should not be applied before the detergent is correctly used).

L. Mix the disinfectant to right quantities, using the recommended dilution rate.

M. Disinfect the house.

N. For earth floors, disinfectant and diesel mixture for drenching the floors only is recommended, following the directions of the disinfectant used and application guidelines (diesel creates an emulsion that helps to bind with the disinfectant into the floor and to achieve an adequate contact time).

- New topsoil should be added, in the house after the first-floor disinfection.

- Disinfection of the new topsoil should be done, by applying disinfectant mixture.

- A non-corrosive disinfectant can be used for the walls and roof.

O. For concrete floors, apply the disinfectant mixture to the roof, walls and floors by following the directions of the disinfectant used and application guidelines.

P. For both earth and concrete floors, allow for adequate contact time for bacterial and virucidal kill.

Farmers should follow the manufacturer’s guidelines on dilution and mixing ratios for detergents and disinfectants to be used. It is always advisable to consult with a local poultry technical expert.

After the disinfection process is complete:

Q. Rest the house for a minimum of 14-21 days.

R. A double disinfection is recommended, with the first disinfection done within 3-7days from last day of collection, and the second disinfection (light disinfection) at least 7 days before placement.

Summary of key steps in cleaning and disinfection for the two floor types

EARTH FLOORS

- Removal and cleaning of all equipment, repairs and maintenance.

- Removal and disposal of manure.

- Dusting to remove webs, sweeping and scraping of the topsoil, removal of residual manure.

- Plain water cleaning.

- Scrubbing the side walls, wire mesh and poles using a detergent and then rinse off with water thoroughly.

- Drench disinfection for the floor.

- Apply new topsoil.

- Topsoil Disinfection.

- Rest.

CONCRETE FLOORS

- Removal and cleaning of all equipment, repairs and maintenance.

- Removal and disposal of manure.

- Dusting to remove webs, sweeping, scraping to remove residual manure on the floor.

- Plain water cleaning.

- Scrubbing the floor, side walls, wire mesh and poles using a detergent and then rinse off with water thoroughly.

- Application of disinfectant.

- Rest.

CONCLUSION

- There are several factors that can contribute to slow growth rates, stunted growth and high mortalities in broiler production, however in this article the focus was on cleaning and disinfection and how shortcuts during this stage are costing broiler farmers in the Zimbabwean context, especially when humidity level rise.

- Moisture and warmth are an ingredient for bacterial activity and multiplication in a poultry house, and if not controlled it can have negative effects on the productivity of a broiler farm.

- Cleaning and disinfection will not completely remove all bad micro-organisms; however, it will reduce the population to give the new chicks a better chance to perform well without fighting infections from the very first day they are placed.

- Routine hygiene swabs are advisable to check for cleaning standard, however the costs are prohibitive to small scale poultry farmers and often their ammunition is in maximizing the clean and disinfection stage with great precision.

NB: These are general guidelines. I wrote this article from my experiences in the poultry industry in Zimbabwe, to share knowledge and with small-scale poultry farmers in mind. I will always advise reader farmers to contact their local poultry technical expert for further farm specific recommendations, because farms are different.

Happy Broiler Farming!