To read more content about AviNews September 2024

To read more content about AviNews September 2024

Content available at:

Indonesia (Indonesian) Melayu (Malay) ไทย (Thai) Tiếng Việt (Vietnamese) Philipino

One of the key parameters in commercial egg production is undoubtedly egg size. The production of high-weight eggs has challenges such as early degradation of shell quality, loss of accumulated eggs by a late start, deterioration of the conversion rate or the increased accumulated mortality.

This is especially true in those countries where the market pays a very high differential price for these bigger eggs.

Egg size has a genetic component as it is a parameter with high heritability. However, changes in bird management and nutrition have an even greater impact than genetics.

The objective of this document is to clarify the key points to adapt egg production to the demand of markets with strong demand for high-caliber eggs. The egg size is based on three pillars:

Bird management

Body weight of birds and size of the egg

It is estimated that for every 45 g above the standard at week 18 of life, there is an increase of 0.5g in the accumulated egg weight at the end of production.

However, if growth occurs in the final part of the rearing it is not effective, as the growth will be in form of fat deposition on the body of the bird.

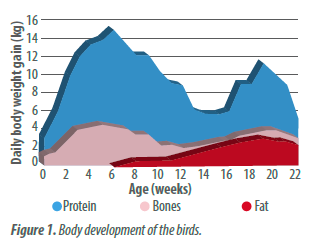

The key period for the development of the bird’s carcass is well known to peak at 6th week of life (as shown in Figure 1).

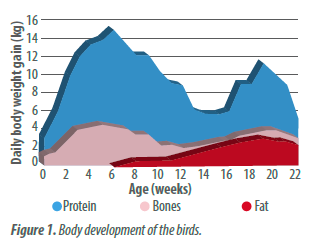

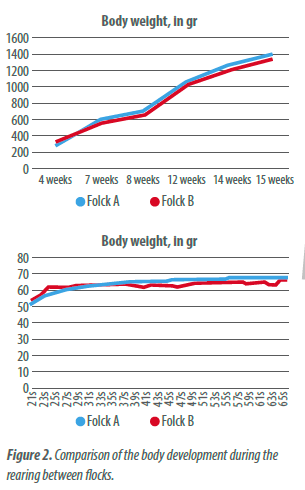

As practical example of how important the body development is during the rearing, it is shown in the next chart two flocks, A and B. Both of them were the same breed, had the same feed, reared in the same cage free system, and taken to the same production barn.

Flock A, which had a higher weight than flock B, at the start of production produced an egg larger than flock B. (See Figure 2).

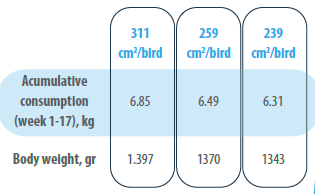

This example corroborates in a field experience what has been demonstrated in published works. For example, Perez Bonilla et al. relate the weight at the end of the rearing to the type of production that the same batch will have during the period of 24-59 weeks of life. These results confirm the important relationship between chick body development and egg production. (See Table 1).

The only way to monitor the body development of the flock is through systematic weighing of a significant sample of birds.

It should be clear that there is no body development without gradual and steady increase in feed consumption.

There is also no satisfactory production without a bird being able to eat enough feed to meet its maintenance and production needs.

Stimulating feed consumption, an essential tool

Stimulation of feed consumption should begin as soon as the birds start the rearing, considering that the body weight of the birds as early as the 6th week will be directly related to the weight of the eggs produced.

During the brooding period (and up to the 4th week of life), it is recommended to feed the chicks with crumb feed if the body weights aren’t achieved continuously. The crumble feed is well accepted by birds, improving consumption, and body and gut development.

One mistake that is usually made when we encounter flocks under the standard body weight and don’t have the correct feed intake is to increase the number of feed runs.

The goal of this management is to activate the birds to eat due to the sound stimulus of the feed system and by the distribution of fresh feed with coarse particles of grain preferred by birds.

It is essential to empty feeders, preferably daily. The application of the feeder emptying protocol can be done from the 4th week of life, when the birds already ingest enough feed volume to allow emptying the feeders, without reducing the total amount of feed that the flock should eat daily.

Emptying feeders has two main objectives:

The digestive tract must be developed so that the hen at the start of the production has the ability to ingest the amount of feed needed to ensure the growth of this period and the production of the first egg.

The easiest way to empty the feeder is simply to let the birds finish the feed until the feeders are completely empty before making a new feed distribution. When feeders are refilled it should be done in two consecutive runs, spaced 30- 45 minutes, to make sure that all the birds eat and not just the dominant ones.

The whole process must be monitored, through daily monitoring of water and feed consumption, to ensure that it is being done correctly. The emptying process of feeders should be applied in rearing and in laying.

In addition to the above-mentioned management, it is necessary to avoid any factor capable of reducing feed intake, such as:

Refer to the H&N Management Guide for more information on recommended flock densities for rearing and laying phases.

Housing density – an important decision

The housing density is a parameter that must be defined before the reception of the birds as it has a direct impact on: the body development at rearing and production period; flock uniformity; and daily feed intake.

High density housing negatively influences the body development of the flock (Table 2) as there is a decrease in feeder and drinking space, and by the stress caused in birds due to the lack of space to show their natural behavior or by increased competition.

Table 2. Impact of bird density on body development during rearing. (CAREY, J.B., (1986), Effects of Pullet-Stocking Density on Performance of Laying Hens)

The role of heat stress

Hens, like any other hot-blooded animals, have biological tools to regulate their body temperature.

However, this capacity is limited; the extended periods of high temperatures can directly affect the bird’s behavior. It could be shown as reduction of the feed intake, reduction of the production parameters, as well as increased of the stress.

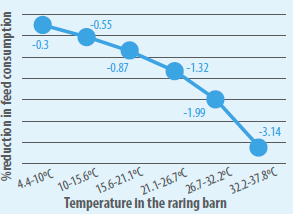

The high temperature of the barn, in addition, has a negative effect on feed intake during the rearing period (Figure 5).

This reduction in consumption has a negative impact on the body development and weight of the bird.

Figure 5. Decrease in daily intake (in %) due to the variation of the average temperature (1°C) inside of the rearing barn. (Bell, D.D. and W.D. Weaver, Jr. (2002) Commercial Chicken Meat and Egg Production. 5th Edition. Kluwer Academic Publishers).

There are several management practices that can be applied to cope with these adverse conditions:

Group feed distributions in periods at periods of the day with lower temperature.

Additional feed delivery at night, in rearing and/or production.

During the production phase, the night light time can be between 60 to 120 minutes, but in any case, this period must be preceded and followed by a period of darkness of at least 3 hours as shown in the next chart.

The same strategy can also be applied during rearing, but if applied from week 12 of life, it can result in early flock stimulus.

Light programs in production

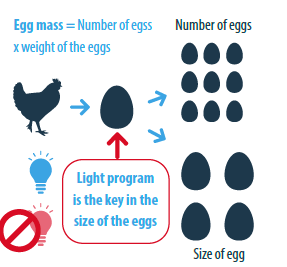

Conceptually, hens activity could be reduced to transforming kilos of feed into kilos of egg mass. This egg mass is the product of the number of eggs laid by the weight of these and depends mainly on the genetics of the bird, as well as applying the correct feeding and management.

However, with a proper light stimulation, it is possible to guide the production of the bird towards one of the two parameters, number of eggs or size of egg.

The hens will start laying eggs when they achieve the mature body weight, when the photoperiod isn’t inhibitory, or they have lost the circadian cycle.

The photoperiods can be classified as:

Stimulanting:

Decreasing or constant:

It is important to note that in commercial laying hens there is no refractory photo period as is the case in other bird species. This means that hens are sensitive to light stimulation from an early age.

It is necessary to work with specific parameters that allow us to make a measurable and repeatable approach when we want to make the optimum light stimulation. Among the most interesting for this purpose are the following:

Age at the start of light stimulation

It is the most used indicator to decide when to start the flock stimulation. Correlates well with weight at the start of light stimulation if the flock has a body weight close to the standard and is uniform.

Otherwise, it can lead to erroneous stimulations that can lead to unwanted production results.

Weight at 50% production

It is a good predictive indicator of what batch production will look like and how the stimulation program has worked. It is very difficult to get the weight exactly in cage systems as it requires weighting the birds after collecting the eggs, but in alternative systems with the new systems on the farm can be easier.

Age at 50% of the production

It is a good predictive data of how the production will be as log as the flock is at the standard body weight and it is uniform. It is more often used than the weight at 50% of production because it is very easy to calculate if the egg production is collected daily.

This data allows a review of the flocks which have produced a right egg size for the production needs and establish a control point for the light program. We can make decisions of which light program suits the production targets.

In the Table 3 there are the different stimulation programs to adjust the egg size to the market needs. These are based on the standard of the breed and should be taken only as an indication.

Nutrition

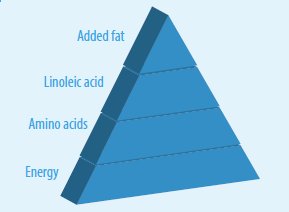

Egg size and nutrition

Egg size can be controlled by the nutrition of the birds, but it will not work if the rest of the key points explained in this text haven’t been completed before.

Energy

Maintenance needs account for 65% of total production needs and except at the beginning of production where bird growth is significant. In the rest of the production, the rest of the energy will be used for egg mass production.

The hen needs its maintenance needs covered before allocating resources to egg-sized production.