Content available at:

Español (Spanish)

There is no doubt that increasing the number of eggs produced per housed hen and doing it with the best possible feeding efficiency to reduce production costs has been, is and will always be one of the main objectives of genetics companies.

However, if we only stick to selecting birds based on the points mentioned above, we would be forgetting certain aspects. These aspects not only have great productive relevance, but above all, they have an extreme economic impact, since up to now we are not considering the wishes, preferences and needs of the customer: ” the egg consumer “.

The final quality of the egg and its presentation will determine the possible success of any commercial action, which will ultimately guarantee the business continuity of the producer (Buxadé et al., 2000).

This is why genetics companies place so much emphasis on increasing the number of “saleable” eggs.

This not only indicates that the product; the egg, must arrive in perfect condition until the moment of purchase by the consumer; but also must be of the highest quality and be produced in an environmentally friendly way, with attention to animal welfare, to ensure and maintain consumer confidence in the product.

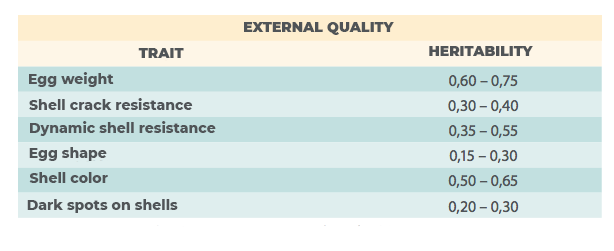

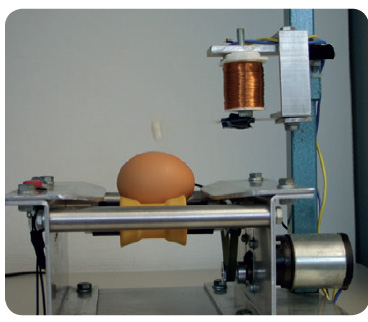

Table 1 presents a summary of the heritability of the different external quality parameters that will be reviewed throughout the text.

Heritability represents the percentage of the total phenotypic variability of a quantitative character that explains the genetic component and, therefore, takes values between zero and one.

It is a parameter of paramount importance for the geneticist, since it determines the possibility that the geneticist has of improving a certain character.

That is, the closer the value is to 1, the easier it will be to obtain an improvement in the character in question through genetic selection.

External qualities include all the parameters that are observable with the naked eye of the consumer. Both the producer and the genetics companies are interested in increasing the number of saleable eggs produced. With this, we want to emphasize that the largest number of eggs possible must have a weight within the range required by the market and that the shell of the eggs must be clean, intact and free of any defects.

Without a doubt, egg weight has always been one of the most important characteristics in a laying hen selection program.

In the first decades of selection, the weight of the egg was significantly increased, to adapt it to consumer demands. In nature, the weight is substantially lower to obtain maximum hatch rates.

Given that different countries have different requirements regarding egg size, it would not be possible to cover the needs of all countries with a single hen.

One of the strategies is to offer the producer the possibility of choosing between birds with different profiles of egg size. In this way, the poultry farmer can; based on the specific requirements of his market, choose:

The difference in egg weight is around 1.5 g above or below the standard layer.

Through this strategy, it is necessary to constantly adopt the objective of selecting the weight of the egg depending on the heterogeneous and constantly changing world market situation regarding size requirements.

During the selection process, the aim is to slightly increase the weight of the egg to counteract natural selection, since larger eggs have a lower hatching rate. In other words, the weight of the egg at a commercial level is maintained or increased slightly from generation to generation.

Egg weight increases with the age of the hen, however the producer would prefer to have a flatter egg weight curve. During the selection process, it is about looking for birds that have a rapid increase in egg weight at the beginning of lay, to reduce the number of eggs less than 53 g, of little commercial value; and a moderate weight at the end of the cycle.

A very high egg weight at the end of the laying cycle can lead to shell quality problems. The weight of the egg measured at different ages is highly correlated (the genetic correlation is around +0.90).

Therefore, birds that lay a large egg size at the beginning also tend to lay larger eggs at the end. However, even though it is not simple, over several generations it is possible to gradually adapt the egg weight curve at different ages, in order to obtain a flatter curve (Flock et al., 2007).

Additionally, the producer can make use of appropriate light programs to achieve an increase in egg weight from the beginning; and later, carry out various management practices, such as adjusting the diet and temperature in the house, to moderate the increase in egg weight once the required weight has been reached.

Although the weight of the egg is a character with a high heritability (around 0.6 – 0.7), the management that the birds receive has a fundamental effect on the size. Differences as substantial as 5 g above or below the standard weight set by the genetics provider can be obtained.

Here are some possible tools that can be used to achieve a greater weight of the egg:

LIGHTING PROGRAM: Carry out a slow stepdown of the lighting period, trying to look for a bird in the rearing phase with a greater conformation in the first 10 weeks of life and later delaying the light stimulation to delay the onset of production.

Obtain a GOOD INTAKE CAPACITY DURING REARING: Train the birds to eat from 9-10 weeks, with the use of feed with less protein content and higher fiber content.

USE OF UNSATURATED FATS AND OILS in the ration during the production phase, which increase the palatability of the food, helping to agglutinate the fine particles in the feed and make an important contribution of energy intake.

Increasing LINOLEIC ACID and SULFURE AMINO ACIDS.

Keep birds in production houses at ENVIRONMENTAL TEMPERATURES BETWEEN 18-22 °C.

There is great variability between individuals in relation to the shell’s resistance to breakage, which, together with its average heritability, allows the geneticist to improve this characteristic considerably generation after generation.

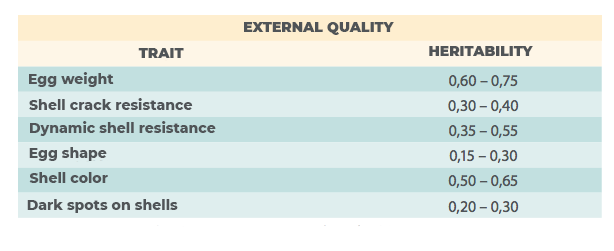

The resistance of the eggshell declines as the bird ages (Graph 1).

Given that there are different devices to measure the shell’s resistance to breakage, care must be taken when comparing values obtained from different devices, since it is common to find significant differences. One of the problems encountered by the geneticist is that the resistance of the shell to break is negatively correlated with the weight of the egg (the genetic correlation is around -0.20), meaning that the largest eggs have worse shell resistance. These correlations are taken into account during the selection process for each of the lines and a balanced selection is made seeking to improve both parameters.

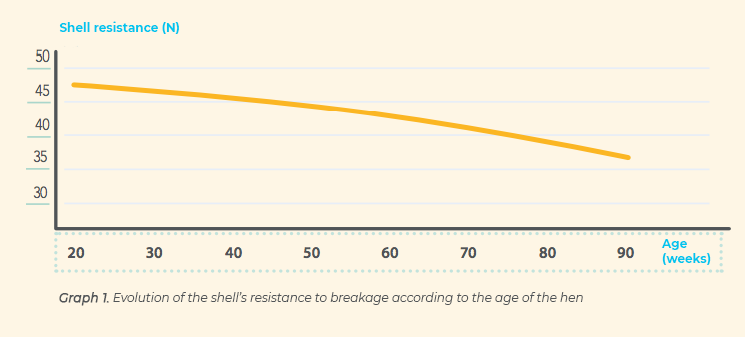

Image 1. Instrument for measuring eggshell crack resistance.

Direct selection on the number of broken and cracked eggs is not very effective, therefore different devices have been developed to measure shell resistance (De Ketelaere et al., 2002).

In order to measure the resistance of the shell, an apparatus is used to put compression on the egg, exerting a progressively greater force until it breaks (Image 1). The device records the maximum force that the shell withstood before breaking. Hartmann et al. (1984) demonstrated that selection response using this instrument was the most efficient method to reduce the percentage of cracked and broken eggs, to the detriment of shell deformation or specific weight measurements.

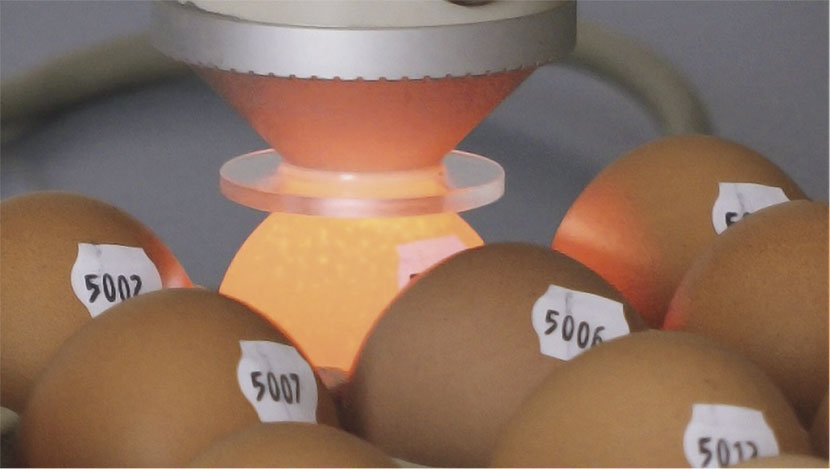

For more than ten years, a new shell stability measure has been incorporated into breeding programs, based on industrial egg detectors used in sorting rooms.

This device was developed by the University of Leuven, Belgium. Coucke (1998) and was the first to introduce this new measure. It is a measure of the resistance of the non-invasive shell, in other words, it is not necessary to break the egg to perform the measurement.

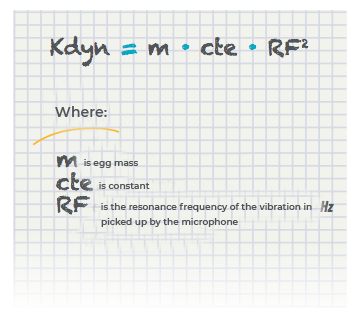

The instrument (Image 2) collects information on the acoustic resonance of the shell and based on this measurement, it calculates the dynamic resistance (Kdyn) of the shell.

Image 2. Instrument for measuring the dynamic resistance of the shell

As it can be seen in Table 1, this characteristic has a heritability superior to the conventional measure of shell resistance.

Dynamic resistance describes the overall behavior of the eggshell and varies little when measured at different points (De Ketelaere et al., 2002).

Furthermore, this measure better reflects the causes for eggs to break and therefore adapts it to the reality of what is being sought in practice.

Eggs with high dynamic resistance (high kdyn value) have been shown to show a significantly lower incidence of breakage throughout the entire production chain (Bain et al., 2006; Mertens et al., 2006).

Both the dynamic resistance and the crack resistance of the egg are integrated in the selection process. The two characters show a positive correlation, indicating that improving one of them indirectly would be improving the other.

However, this correlation is well below one (the genetic correlation moves in values of 0.4 – 0.6), indicating that both measures are collecting information on different properties of the shell.

The breaking strength has a high correlation with the percentage and the thickness of the shell, while this correlation is much more moderate in the case of dynamic resistance (Icken et al., 2006).

Furthermore, the dynamic resistance measurement has the advantage of having a lower negative correlation with the weight of the egg than the crack resistance of the eggshell.

One of the points that is still unclear, is why the dynamic resistance measurement does not decline as the age of the hen increases as might be expected (Blanco et al., 2014), as it is well known, and as can be seen in Graph 1, the shell crack resistance does.

Reducing a flock by 1% of declassified eggs means about 3 more saleable eggs per housed hen.

Additionally, indirectly, the chance of these eggs breaking and dirtying others on the belts will be reduced during collection. Therefore, as a whole and depending on local market conditions, we can be talking about an additional net profit of € 0.14 per housed hen.

What is even more important: the shell quality of the flock will be one of the main determinants of the flock’s output to the slaughterhouse.

Genetics companies have been working on preparing the hen to go to cycles above 90 weeks without the need to molt, therefore only those hens and those flocks that are capable of maintaining good shell quality to the end will be able to take full advantage of the genetic potential of birds.

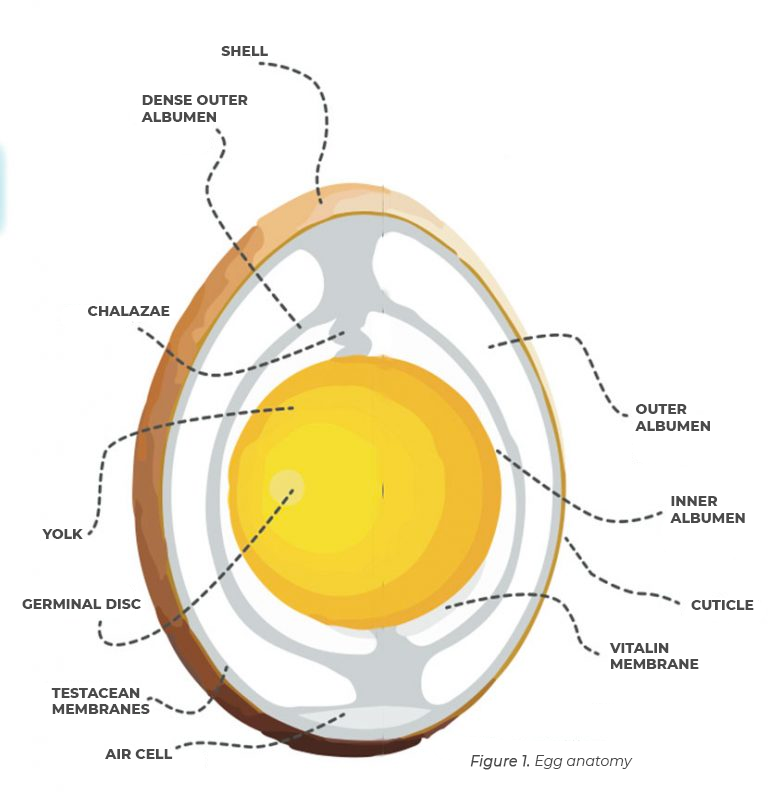

Therefore, we can conclude that the economic impact of this characteristic is tremendous. The egg formation time in the oviduct takes just over 24 hours. The shell represents around 11% of the total weight of the egg. The hen has to complete the formation of a perfect shell inside the uterus, which requires approximately 20 hours.

Hens in production have the highest demand for nutrients during the time of the eggshell formation, which occurs mainly during the afternoon and night.

That is why we recommend that two thirds of the volume of feed that the birds should consume in the afternoon be administered … our birds should “go to sleep on a full stomach”!

Birds have rapidly soluble calcium needs (particles less than 1 mm in diameter), which will be used metabolically under normal conditions during the day. As well as slow solubility calcium needs (particles greater than 2 mm in diameter and preferably 4-5 mm) that will be retained in the gizzard to be used overnight in the formation of the shell (Díaz, 2011). Our recommendation is to maintain a proportion of 70% coarse particles and 30% fine particles of calcium carbonate and gradually increase the proportion of coarse particles at the end of the cycle.

The cuticle plays a key role in protecting the egg against bacteria entering it. The presence of the cuticle can be determined by staining the egg, so that when it is present, the shell is stained green.

With this method, the presence of cuticle can be quantified by calculating the color difference between the egg before and after being dyed. Bain et al. (2013) using this method estimated that the heritability of this character is 0.27 and it could be used in selection programs.

“The worse the quality of the cuticle, the greater the risk of contamination of the egg”

The shape of the egg is of commercial interest, since the consumer does not willingly accept excessively elongated or too round eggs; in addition to the possible breaks that may occur, since they do not fit correctly in the cartons when they are packaged.

An index is calculated that consists of dividing the width by the length of the egg and expressing it as a percentage. In this way, eggs with an index below 72 will be extremely long and those with an index above 76 will be extremely round (Buxadé et al., 2000).

In addition, eggs that are extremely round make it difficult to identify the large end from the narrow end, presenting a challenge when it must be placed in the incubation trays.

An incorrect placement of the hatching egg in the incubation trays will cause a significant decrease in hatchability.

The shape of the egg has a positive correlation with the resistance of the egg (+0.40).

That is why the shape of the egg is a characteristic that is recorded routinely and paid attention to during the selection process, to keep the ideal shape of the egg. If not, given the emphasis on improving shell strength, the eggs would become increasingly round.

Although the color of the shell has no influence on the nutritional value of the egg and is a purely aesthetic feature, it has a determining value in relation to consumer preferences.

In the case of brown eggs, an intense brown color, attractive and homogeneous inside the egg carton, is a key point when it comes to marketing and consumer acceptance.

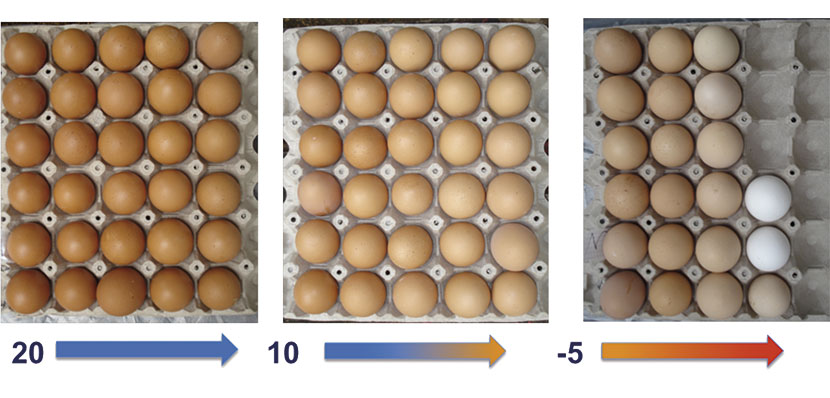

As it was shown in Table 1, it is a characteristic of high heritability, so it has been improved substantially through genetic improvement. The color of the shell is measured with a spectrophotometer (Image 3).

Eventually, an index was built based on the parameters supplied by the device. The lower the value of the color index, the darker the color of the shell (Image 4). This value moves from slightly negative values to values above 90. Eggs with a paler shell color are often heard to be more brittle.

Picture 3 . Spectrophotometer to measure shell color

Image 4. Color index of the shell

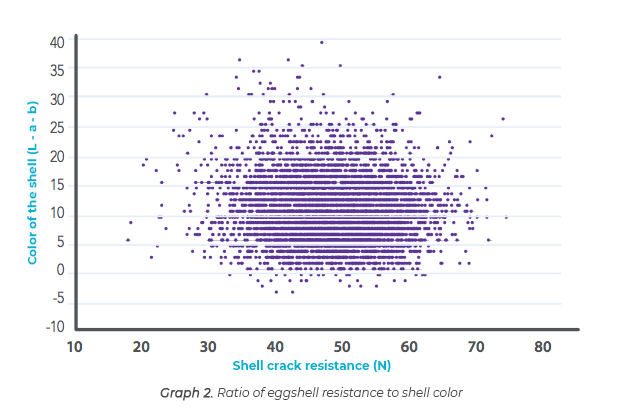

This is probably due to the fact that as the chicken ages, the color of the shell becomes paler and, as previously mentioned, the shell loses resistance. In the nuclei of pure lines, when we analyze eggs from hens of the same age, as can be seen in Graph 2 (following pages), we did not find any correlation between shell color and shell resistance.

In other words, improving one of the two characters will have no effect on the other. There is no cause-effect relationship: poor shell color implies breakage problems. However, in the field, the color of the shell can be used as an “alarm parameter” since an unexpected drop in color may indicate that there is a problem in the flock, which is possibly also affecting the stability of the shell.

“A bad eggshell color does not imply breakage problems, but it can be an alarm parameter since an unexpected color can indicate a problem in the flock”

The real cause of this poor quality of the shell can be (among others):

The pigmentation of the shell that is carried out in the last hours of its formation, can also be affected if this formation has not occurred correctly.

The correlation that exists between the color measurements at different ages is high (0.8 – 0.9), so the birds that lay darker colored eggs at the beginning of lay will also make them darker at the end of the production cycle.

One of the characteristics that is positively correlated with the brown color of the shell (the genetic correlation is around 0.30), is the presence of dark-colored freckles on the surface of the shell (Image 5).

Image 5. Dark freckles on brown eggshells.

Both, the color of the shell and the incidence of freckles are taken into account during selection process. Despite the positive correlation that exists between both characteristics, it is possible to improve the color of the shell while slightly reducing the incidence of freckles.

Anecdotally, especially in the field of production in ecological and rural systems, the consumer appreciates the presence of these freckles as a sign of small imperfections and biological variability, which make this consumer perceive that it is a more natural product.

Refers to the appearance of discolored or translucent areas within the shell. It is more apparent in white eggs than brown eggs and is due to an accumulation of water in the shell.

The eggs do not look like this during oviposition, but mottling can start to appear half an hour later.

The heritability of this characteristic is moderate at 0.3 – 0.4, so genetic improvement works to reduce the incidence of this problem.

This problem is normally associated with eggs stored in environments with high relative humidity, or with eggs that have been quickly moved from high to low temperatures.

Especially in hot and high humidity climates, it is advisable to collect the eggs several times a day and take them as soon as possible to a well-equipped storage room where, gradually, the eggs will be conditioned to the ambient conditions of the storage rooms.

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón