17 Jun 2020

Is it Time to Get Rid of Minimum Ventilation Tables?

To understand why minimum ventilation tables are problematic we must first understand that minimum ventilation tables have nothing to do […]

To understand why minimum ventilation tables are problematic we must first understand that minimum ventilation tables have nothing to do with controlling oxygen, carbon dioxide, carbon monoxide or even ammonia levels in poultry houses. In fact, they are all designed to do just one thing: help producers manage house moisture levels. Specifically, they provide an estimate of how much ventilation is required to rid a house of moisture the birds are adding to it for a given age and/or weight.

If a lower ventilation rate is used, then not all the moisture the birds are adding to the house will be removed and moisture levels build up in the air and the litter. If a higher minimum ventilation rate is used, more moisture will be removed from the house than the birds are adding to the house and moisture levels will tend to fall. This is true of all minimum ventilation recommendations whether they are provided by a poultry company, equipment company, primary breeding company, text book, or university. They all provide a theoretical minimum ventilation rate to remove the moisture the birds are adding to a house. The key word here is theoretical.

To calculate a moisture control ventilation rate you need to know

1) How much moisture the birds are adding to the house

2) How much moisture the drinker system is adding to the house (water not consumed by the birds)

3) Inside temperature and humidity

4) Outside temperature and humidity

These values can then be plugged into a series of equations and a moisture control minimum ventilation rate can be calculated. This value can then be divided by a theoretical number of birds or their weight and a table can be developed

If you are going to use one of these tables to determine how much to run your minimum ventilation fans, remember that there are a number of very important assumptions that need to be made when using these equations:

- A specific house temperature is being maintained and it is constant for a given bird age or weight. Change the house temperature +/- 5 F, the required minimum ventilation rate can change +/- 25%.

- A specific house humidity is being maintained and it is constant at a given bird age or weight. Change the inside humidity +/- 10%, the required minimum ventilation rate can change +/-25%

- A specific amount of water is being added to the house for a given bird age or weight. Change the water consumption +/- 10%, the required minimum ventilation rate can change +/- 10%.

- Outside environmental conditions are constant for a given bird age or weight. Change the outside temperature +/- 10 F, the required minimum ventilation rate can change +/- 15%.

- All the incoming air is throughly mixed with the inside air:

- a) All the fresh air enters though a house’s air inlet system (i.e, no leakage).

- b) Proper inlet opening and static pressure are being maintained.

- c) The air inlets are properly designed and maintained. A loose house can easily require minimum ventilation rates to be increased 20% or more due incoming air not being properly heated and dried before moving down to floor level. It takes more cool damp air to dry the litter than warm dry air.

- The air moving capacity of the minimum ventilation fans is precisely known. Change the output of the fans +/- 10%, the required minimum ventilation rate can change +/- 10%.

- No moisture is being added to the house by the heating system. For every gallon of propane burned, approximately 0.8 of a gallon of water is added to a house. During brooding the heating system can be easily be adding 20% or more of the water we need to remove.

- The fresh air is brought in uniformly along the length of the house. 9) The inside temperature and humidity are uniform throughout the house.

As a result of this wide variety of variables a person creating a table that provides a weekly suggested minimum ventilation rate on a per bird or bird weight basis needs to

- Estimate the average amount of water consumed by the birds over the week which will vary based on the breed of bird, feed formulation, weather, bird health, etc. From this they need to estimate how much water was retained by the birds and how much was returned to the house in the form of moist air and wet manure. They also need to estimate what percentage of the moisture was directly added to the litter due to leaky nipples and bird wastage.

- Assume a specific and constant inside house temperature and humidity for the week/day

- Assume a specific and constant outside temperature and humidity for the week/day

- Assume a perfectly tight house as well as a perfectly operating environmental control system

Literally dozens of assumptions made by the designer of a minimum ventilation table have to be correct in order for the table to provide an accurate minimum ventilation rate. The problem of course is the user doesn’t know what assumptions were made in developing the table and whether they apply to their particular situation. Was the table developed assuming the house is in Germany or Alabama? Was it assumed the house had a new drinker system or older drinker system? Was it developed assuming a curtain-sided house or a totally enclosed house? The list goes on. The more the assumptions made vary from what is actually happening on a particular farm, the more inaccurate the minimum ventilation rate provided by the table will be and the further air quality/bird health/heating costs will be from ideal.

If the tables are so potentially problematic why were they developed in the first place? Minimum ventilation tables are not a new concept.

The first tables became popular over 40 years ago as exhaust fans were first being installed in traditionally naturally-ventilated houses as a method of more precisely controlling the amount of fresh air being brought in to a house during cold weather. Long before this, engineers and scientists knew that minimum ventilation rates should be primarily based on house moisture levels, specifically humidity.

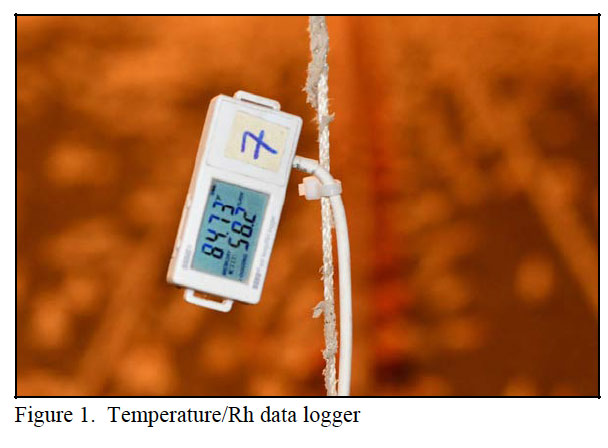

Research then and now has shown that when the humidity is under control the other air quality variables such as, carbon dioxide, litter moisture, dust, and ammonia will be controlled as well the vast majority of the time. Relative humidity is simply the best overall indicator of air quality. But, in the past, measuring humidity was difficult and labor intensive. It involved using a sling psychrometer to measure wet bulb and dry bulb temperature then using a table to calculate the relative humidity. Digital humidity meters were extremely expensive and as a result relegated to laboratories, not poultry houses. The tables were developed to provide a very rough estimate of the amount of ventilation required to control moisture and therefore air quality. They provided growers a starting point. They were in a sense a necessary evil….they were better than giving a grower no guidance at all on minimum ventilation rates.

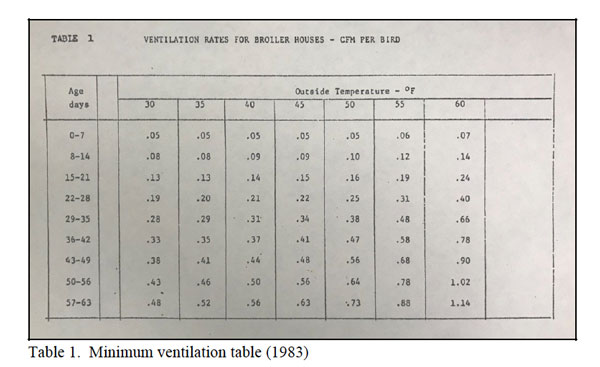

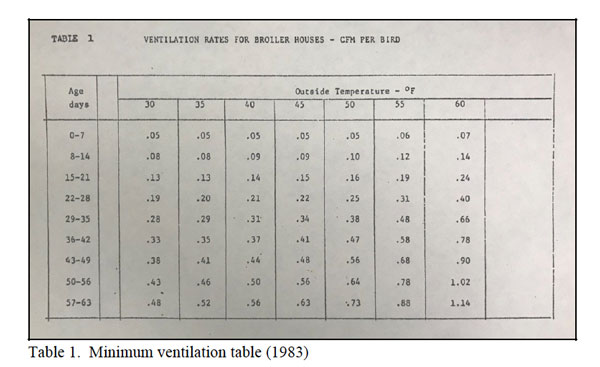

Table 1 illustrates a minimum ventilation table from the early 1980’s. This particular chart does attempt to take into account outside temperature in providing a minimum ventilation rate, which many modern tables do not. The minimum ventilation rates listed tend to be lower than most used today because the birds were growing much slower than they do today and as a result were drinking less water (eating less feed), especially at younger ages, so less water needed to be removed from a house.

The question is why we continue to use tables to determine our minimum ventilation rates when digital humidity sensors are readily available to help poultry producers accurately determine if they are ventilating enough during cold weather. After all, we don’t use a heater runtime table to determine how much we need to run our heaters. We measure the temperature, through our controllers, and our heaters operate accordingly. We need to start thinking about air quality control the same way. The best measure of air quality is humidity. We should continuously monitor house humidity then make the necessary adjustments to our minimum ventilation fans run time to maintain the desired level of humidity. If the humidity is too high, minimum ventilation fan runtime is increased. If it’s too low, runtime should be decreased. It is really that simple.

Humidity sensors are too often thought of as a luxury item. Though modern humidity sensors are relatively expensive, running between $200 and $300, and probably have a realistic life of only a few years, they are in fact well worth the expense. A humidity sensor in fact is actually quite inexpensive when looked at in terms of what a single sick flock caused by poor air quality or single high fuel bill due to over-ventilation can cost a producer/company. Furthermore, a typical poultry house may have six or more temperature sensors that in total cost far more than a humidity sensor. Few people could properly manage house environment, and/or heating costs without temperature sensors telling them what is happening in their house. The same holds true when it comes to having a humidity sensor helping to manage bird health and welfare.

What is the ideal humidity for a poultry house during cold weather? Around 50%. But the ideal is not always achievable, economical, or for that matter necessary. In fact, the acceptable range is generally recognized to be between 30 and 70%. As is the case with house temperature, the precise target humidity is debatable and can vary from farm to farm as well as over the course of the flock. However, what is not really debatable is that if we want to control air quality producers need to have a way to objectively measure it, and humidity is what producers should be measuring and trying to control

Managing air quality through the use of a humidity sensor is pretty straightforward. During preheating, a producer would provide a nominal minimum ventilation rate of somewhere between 0.05 and 0.1 cfm per chick to be placed. This should be viewed as a starting point. This ventilation rate should help rid the house of excess moisture emanating from the litter as well as that being produced by combustion of propane/natural gas. In addition, fresh air is needed to reduce the build-up of carbon dioxide being produced by the heating system.

Starting the day after the heating system is turned on minimum ventilation rates should be based on what is actually happening in the house, specifically humidity levels. Early each morning the relative humidity should be checked because this is when it tends to be the highest, and as result air quality tends to be the worse. Ideally, this measurement should be recorded each day on graph paper. Farm managers should look for trends. Is the humidity increasing, decreasing, or stable? If the humidity is around 40 – 60% and stable, probably no changes need to be made to minimum ventilation fan runtime. But, if the humidity level is trending upward and is climbing toward 60%, minimum ventilation rates must be increased.

The quicker a manager reacts to an increase in humidity, the smaller the increase needs to be made to the minimum ventilation rate. It is important to note that at times minimum ventilation rates can be decreased without harming air quality. For instance, if humidity levels are decreasing due to changes in the weather, it is perfectly acceptable to reduce minimum ventilation rates. Again, it is really no different than controlling house temperature. If the house is too hot/humid, ventilation rates should be increased. If it is too cold/dry, ventilation rates can be decreased. As birds get older it will tend to become more difficult to control relative humidity and as a result higher levels (i.e. 70%) are often viewed as acceptable.

What about carbon dioxide? The fact is that a minimum ventilation table developed to control moisture does not assure that the desired carbon dioxide concentration will be maintained. As is the case with moisture control, if you have a specific carbon dioxide concentration target, the only way to ensure that target is being met is by measuring it on a continuous basis. It is next to impossible to develop a minimum ventilation table to precisely control carbon dioxide because during cold weather most of the carbon dioxide is typically being produced by a houses heating system and heating system run time varies tremendously from house to house, farm to farm, day to day. This being said, in most cases, if proper humidity levels are maintained, carbon dioxide concentrations do not tend to be problematic.

It is really quite simple. If you want productive, healthy birds, put away the minimum ventilation table and install a quality humidity sensor. Keep as close as an eye on humidity as you do temperature and adjust your minimum ventilation runtime based on what is actually happening in your house and not on dated, theoretical tables.