26 May 2020

Optimal management of aerial feed distribution to optimize broiler breeder uniformity

Content available at: Español (Spanish)In this particular scenario, the available feeder space becomes a limiting factor, which sometimes requires a […]

Content available at:

Español (Spanish)

In this particular scenario, the available feeder space becomes a limiting factor, which sometimes requires a reduction of density. By feeding the birds on the ground, we greatly eliminate this limitation, allow all individuals to consume the feed at the same time and therefore improve the uniformity of the flock. IT IS IMPORTANT TO NOTE THAT DIGGING AND PICKING ARE PARTS OF THEIR NATURAL BEHAVIOR.

Wood chip should be the material of choice when it comes to floor feeding. Correct management of ventilation, heating and drinking water is essential to ensure that the chip gradually degrades into a dry and friable litter.

The litter should become a dark, almost black powder, in this way the granules will contrast by color difference and it will be easier for the birds to locate feed. Rice husk and similar materials, which remain undisturbed, should be avoided.

During the time that the birds are consuming the feed, they dig for the granules and at the same time mix it with the litter.

The litter should not exceed 4 cm in depth in order to avoid feed loss.

To achieve a 4 cm depth, we would have to initially distribute it at 2 cm: To ensure the comfort of the birds, the houses should be properly preheated 24 hours before the arrival of the birds.

A quality granulate, and therefore good durability, are essential if we are to use an aerial food distribution system.

Consequently, the percentage of fine particles increases and these are irreversibly lost during the distribution of the feed; the result is a decrease in the feed available to birds.

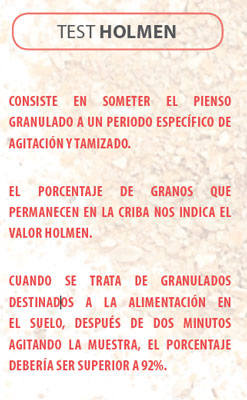

Constant assessment of the durability of the granulate is therefore essential. A widely used system in factories to make this assessment is the Holmen test. Raw materials have a significant effect on the quality of the granulate. Wheat-based diets give us higher durability values, since during the conditioning and the granulation process a gelatinization of its starch occurs. On the other hand, corn-based diets usually have lower durability values, as a consequence of less gelatinization.

Therefore, at least 45% of wheat should be added if we want to achieve correct durability values.

The broiler breeders receive continuous feed increases during their rearing and, consequently, they should respond with constant and uniform increases in weight.

Heterogeneity in pellet quality between different deliveries made to a farm and/or correct feeds switched with low durability feeds with excess fines, will cause a lack of predictability of weight increases and eventually cause a sawtooth-type growth curves.

In the rearing farm, screens can be installed on the conveyor and thus eliminate the fine particles that may have been created during the transport and unloading of the feed.

The consumption time of the feed has a direct influence on the homogeneity of the flocks.

IF BIRDS CONSUME FEED QUICKLY, THE RESULT IS A VARIABLE FEED INTAKE AMONG INDIVIDUALS AND THEREFORE WE WILL HAVE HETEROGENEOUS FLOCKS.

The duration of feeding at rearing should ideally be between 30 and 45 minutes; however, when the birds are fed on the ground, the duration is usually shorter and often takes about a quarter of an hour.

The length of the granulate is related to the time that the birds need to consume the feed. Very long grains reduce the consumption time and therefore impair the uniformity of the flock.

In any case, short granules should only be produced when correct durability can be ensured, if we have screens and if the litter is shallow and friable.

In the transition phase between the crumb of the rearing feed and the granulate of the growth feed, the texture of the feed should be between a coarse crumb and a short granulate. It is a matter of gradually conditioning the birds to the new texture.

Therefore, producing long grains between 14 and 15 mm in length in the factory should be avoided, since the birds end up consuming grains of 10 to 11 mm and the consumption time will be too short. The objective should be to produce short grains, between 9 and 10 mm in length; then the birds will end up consuming grains of 5 to 6 mm and this will lengthen the duration of the feeding time.

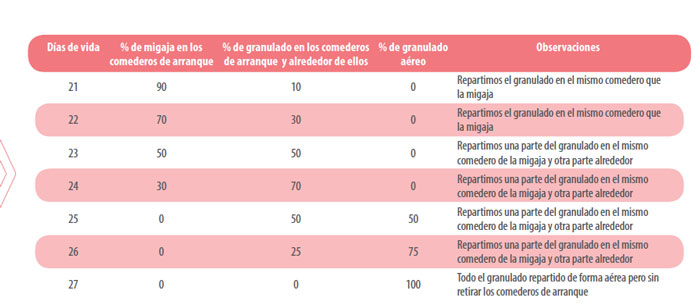

During this phase there are two rules that should always be respected to prevent flock uniformity from degrading:

- Do not start the transition until 21 days of the birds’ life

- Make the transition gradually

The change from a crumbled feed to a granulate is always a challenge for the herds. Although the grains are short, 5-6 mm long, all birds have to be able to ingest them. Within the flocks there are smaller individuals that may have a physical difficulty in consuming the granules, so starting the transition at 21 days we guarantee that all the birds are able to ingest it.

The birds that make up a flock have different characteristics of conformation, weight and beak shape, they are different individuals, and therefore some will get used to eating granulated feed fast than others.

By making the transition from crumb to granulate slowly and gradually, we give the birds more time to adapt and thus avoid significant drops in uniformity.

We should bear in mind that both the texture of the feed and its delivery method are being altered simultaneously.

The table below shows how to correctly make the transition from crumb to granulate (Table 1). At the beginning of the process we should place the starter feeders around the overhead distribution hoppers.

In this way, when the granulate on the floor is introduced into these troughs, the birds will associate it with food. These feeders will be left on the surface of the litter until 30 days of the birds’ lives, although at that time the entire distribution is aerial, the objective is to give more opportunities to the birds that are lagging behind to learn to eat the granulate.

Before laying the new litter on the ground and therefore before the birds enter the farm, the correct operation of the aerial delivery hoppers must be tested. It is a matter of putting them into operation with a little feed to check if they spread evenly on the ground.

During the transition and up to 6 weeks of the bird’s life, the hoppers should be adjusted to distribute the feed over approximately half of the surface; that is, if there are 7 meters between the hopper and the wall, it would only have to fall within a radius of about 4 m (the other 3 meters until reaching the wall should not have feed).

The small size of the birds at the beginning of rearing means that many litter spaces are left free during feeding. Then the more skilled individuals ingest much more feed than they should and the flock becomes uneven.

There is also the added risk of having stuffed birds and therefore, mortality.

Table 1. Process of changing from crumb to granulate

- After 42 days, the hoppers should be distributed over 100% of their circumference, always preventing the granulate from hitting the walls.

- As a general rule, each hopper should be for 1500 females or 1000 males.

- Even with a good transition, flocks often lose uniformity in this phase.

- It is therefore important to carry out the first weighing and individual selection of the birds one week after the end of the transition phase.

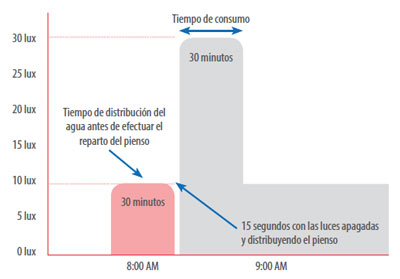

Correct management of water distribution, feed and light intensity aims to allow birds to consume the feed in a homogeneous way.

We should turn off the light for about 15 seconds while feed distribution begins.

There are two reasons why birds should have access to water before distributing the feed:

- Avoid stuffing. If there are birds that come from the previous day with herder crops, they will have the possibility to drink before consuming feed again.

- Have a uniform distribution of the birds before distributing the granules. The birds should not be allowed to associate the light with the distribution of the feed, they must be given ½ hour of water and light before distributing the feed so that the birds calm down and stop moving.

During the initial half hour in which the birds have access to water, the intensity of the light should be approximately 10 lux, to avoid excess activity and allow the birds to distribute themselves evenly.

The aim of this management is that the birds have an initial volume of feed distributed on the floor when the lights are switched on again, so that they start consuming without moving around and therefore in a calm manner (Figure 2) .

While the birds are eating, light intensity should be raised to 30 lux, in order to facilitate feed detection and thus, ensuring their complete consumption. Caution must be exercised, if light intensity is too high, it will cause stress, as well as cloaca and feather pecking.

ONCE THE FEED HAS BEEN CONSUMED, IT MUST RETURNED TO 10 LUX

Regarding water consumption, it is important to control the water:feed ratio and change it depending on the temperature, relative humidity and the state of the litter.

However, the key point for making decisions regarding water consumption should be the condition of the crop. If the birds have ingested enough water, the crops should not be hard to the touch. Keep in mind that a reduced intake of water will have a negative impact on the digestion process and on the uniformity of the flock.

Figure 2. Light management pattern during the distribution of water and feed.

Ideally, the houses should be divided into square pens, with the length of their sides corresponding to the width of the house.

A hopper should be located in the center of each pen. In this way, the densities throughout the house would be uniform and the number of birds consuming under each distribution hopper would be very similar.

As a general rule, in farms up to 14 m wide, to correctly position the hoppers there are two distances that should correspond to the width of the house:

- The distance between the hoppers

- Diameters of feed distribution circumferences

The aim for such a configuration is to avoid:

- Granule distribution circumferences overlapping and that therefore the distribution of the feed is disrupted.

- That the feed hits and accumulates against the walls.

Within the distribution circumference of the feed it should be evenly distributed.

The material located inside the pens, such as hangers or perches, should be placed in the corners, to avoid that the granules hitting them and disrupting feed distribution.

The key points to optimize uniformity when using aerial feed distribution are:

- Litter depth of 4 cm.

- Use litter materials that degrade to a dry, dark, friable litter.

- The granules should have a minimum durability of 92%.

- Screen the granules in the feed mill and on the farm.

- The length of the distributed grains should be 5 to 6 mm.

- The ideal consumption time should be 30 minutes.

- Distribute the feed with an intensity of 30 lux to avoid nervousness.

- Feeding grains should not be noticed when feeling the crop if the volume of water distributed has been sufficient.

- Carry out the first weighing and individual selection one week after finishing the crumb-granulate transition.

- The distribution of the granulate in the soil must be uniform.