The issue is that safety margins are greater than necessary because of a lack of standard deviation in the records. Consequently, there is no clear knowledge of how ingredient nutrients can vary.

Poultry companies could be losing $19 Million (USD) per year

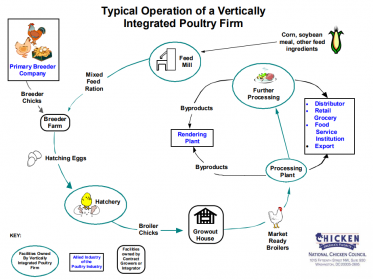

In the poultry industry, some companies are composed of a complex network of production systems that are interconnected. That is why those companies are called integrations or integrated operations. Hatcheries, poultry farms, feed mills, and even fields of crops and logistics companies of transport can belong to this kind of industry.

In the poultry industry, some companies are composed of a complex network of production systems that are interconnected. That is why those companies are called integrations or integrated operations. Hatcheries, poultry farms, feed mills, and even fields of crops and logistics companies of transport can belong to this kind of industry.

Source: National Chicken Council

Several reports have demonstrated that feed can represent about 65% of the total production cost in most poultry productions. Thus, a suitable feed formulation is necessary to keep a profitable system. However, poultry diets tend to be nutritionally overestimated or underestimated, accounting for extra production costs or profit reduction. These changes in the dietary nutrient concentration have been previously described and come from the high nutrient variability of the feed ingredients.

The Association of Analytical Chemists (AOAC) regularly releases different methodologies for feed ingredient analysis. These methods are broadly known and usually are implemented in feed mills. Still, the majority are considered time-consuming but more accurate. The use of near-infrared (NIR) calibrations, which allows the instantaneous estimation of nutrient composition, is the most common technique adopted in feed mills. Despite this system's speed and precision, its result can be as representative as the sample analyzed. Additionally, delays in delivering results are frequently a concern among nutritionists in large companies, while consultants in this area may not have access to this technology.

When these situations arise, nutritionists tend to consult nutritional tables (book values) or historical records of the feed ingredients to add safety margins to diets. This allows commercial feed companies to comply with the minimum legal requirements established, while in the integrations, it prevents the animals from obtaining insufficient nutrients that can affect performance.

How does improper sampling and variability affect nutrients in broiler diets?

In the upcoming issue (March, 2021) of the Journal of Applied Poultry Research, researchers from the University of New England in Australia performed 10,000 simulations to evaluate the variability in Crude Protein of starter, grower, finisher, and withdrawal broiler diets. Simulations were based on the mean, and standard deviation of dietary components to estimate the likelihood a diet mixed to optimal specifications may fall below recommendations.

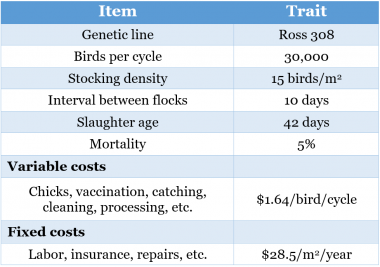

Management parameters were considered as follows:

The authors demonstrated that within withdrawal diets formulated to 19.2% CP from nutritional tables, there is approximately a 10% chance that the diet will end up with less than 18.2% CP. However, just by improving wheat analysis accuracy, the probability of getting underestimated diets would be less than 5%. The gross profit was also affected by 63 and 21% when diets were lower or higher in nutrients, respectively.

"Thus, it is possible to incur a difference of up to $19,053 (USD) in gross margin from one cycle of 30,000 broilers by simply overestimating the nutrient content of feedstuff. Assuming a poultry company may produce approximately 1,000 broiler cycles per year, this equates to a loss of up to $19 million (USD)."

Some recommendations to improve accuracy of feed formulation:

- Use NIR in stream samples obtained from the unloading process. (This is to improve your data collection, not for ingredient approval)

- If multiple batches of the same ingredient must be combined into one single hopper, take a sample from each batch and report all results to the nutritionist.

- Formulate diets via stochastic means as an alternative to a safety margin.

For more information, visit: