Content available at: العربية (Arabic)

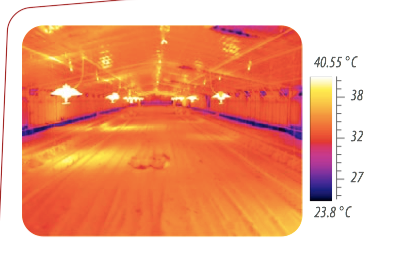

Figure 1. Thermal image end of broiler house heated by radiant brooders

Feeders as well as supplemental feeders are full of feed and the water lines set to the proper height.

Minimum ventilation fans are operating 30 seconds out of five minutes and the humidity is approximately 60%.

Figure 2. Controller display day of chick placement

Both types of heating systems can, and have been, successfully used for decades to provide the supplemental heat during brooding, but that being said, they heat a house very differently.

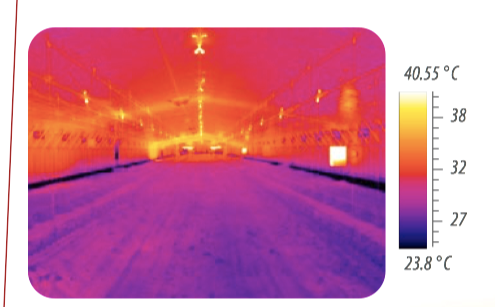

Nothing makes this point more clearly than when the thermal image of the end equipped with forced air furnaces (Figure 3) is compared to the end heated by the radiant brooders (Figure 1).

Figure 3. Thermal image of end of broiler house heated by forcedair

furnaces

![]() The controller indicated that the air temperature on each end of the house was essentially identical, but thermal images tell a different story.

The controller indicated that the air temperature on each end of the house was essentially identical, but thermal images tell a different story.

![]() Although the floor temperature on the radiant brooder end was between 87oF and 102oF, the floor temperature on the end heated with forced-air furnaces was between 78oF and 87oF…roughly 10oF cooler.

Although the floor temperature on the radiant brooder end was between 87oF and 102oF, the floor temperature on the end heated with forced-air furnaces was between 78oF and 87oF…roughly 10oF cooler.

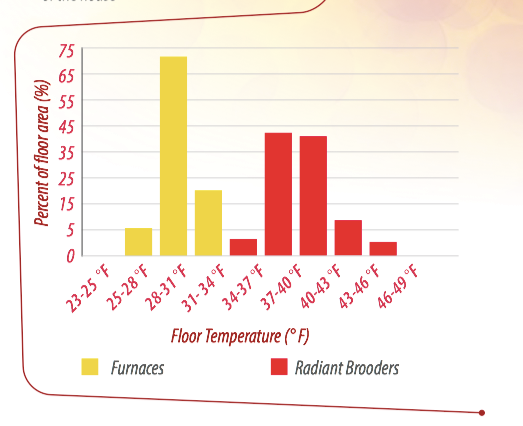

Figure 4 is a histogram of floor temperatures on each end of the house.

On the end of the house with furnaces 72%, of the floor area was between 81oF and 84oF.

On the end with radiant brooders, 85% of the floor was between 90oF and 96oF.

Figure 4. Floor temperature profile on each end

of the house

Keep up to date with our newsletters

Receive the magazine for free in digital version

REGISTRATION

ACCESS

YOUR ACCOUNT

LOGIN

Lost your password?