Pre-slaughter challenges: How to reduce losses in quality and performance

Contenido disponible en: Español (Spanish) This peculiar situation that is observed in many Latin American and Spanish companies, has enormous […]

This peculiar situation that is observed in many Latin American and Spanish companies, has enormous economic repercussions in terms of final weight output of Grade A quality chicken meat that are produced daily in slaughter plants, affecting the degree of competitiveness in an increasingly demanding and aggressive market. During the brooding and fattening stages of flocks, technical-administrative monitoring can be similar to that carried out by air traffic controllers, in order to guarantee within their level of responsibilities that all assigned flights reach their final destination.

- Day-old chicks from hatcheries are transported in specially designed trucks, in order to reduce all factors potentially affecting their comfort and well-being, which can lead to their deaths.

- The houses and farms have been carefully prepared to receive the new flock.

- The technical and operational personnel have all the infrastructure necessary for the daily evaluation of the birds, avoiding as far as possible any health and flock management problems that can affect their quality and fattening process.

- When an event occurs that may jeopardize the technical and / or economic results of the flock, the respective Action Plan immediately goes into operation.

All farm staff and company management are closely monitoring the fattening process. The reason for this behavior is based on the fact that if there is product to send to the processing plant, there is no business, preventing the recovery of all the investment made.

Once it has been confirmed that the birds have reached the weight that the slaughterhouse demands, the pre-slaughter stage begins. The pre-slaughter stage has a significant impact on the overall quality and performance of the chickens to be processed. During this stage three critical activities are carried out:

- FASTING

- COLLECTION AND CAGING

- TRANSPORTING CHICKENS TO THE PROCESSING PLANT

On the one hand, the poultry production group thinks that its responsibility ceases when the order to start the fasting is given.

On the other side of the coin, plant management is convinced that its responsibility begins when the birds arrive at its facilities, despite the fact that among other details, the cages are emptied, washed and disinfected there, before being returned in the trucks to the farms.

Given the magnitude of this costly daily problem that is noted in many companies, it is important to remember a set of specific details that we know and should be monitored in real time, in each of these operations.

FASTING

It has been defined as the time when we stop feeding the chickens until the moment of their slaughter. It has been established that ensuring 8 to 12 hours of fasting is adequate to allow the evacuation of their intestinal tracts.

Insufficient fasting If less than 8 hours, problems will arise resulting from insufficient fasting

Over-fasting If exceeds 12 hours, problems of over-fasting may appear.

FACTORS TO MONITOR

The bell or nipple drinkers must always have enough water. Remember that chickens are sectorial. If they do not find water in the regular place where they're used to, they lie down. Water facilitates digestion, since the food is moistened.

BIRD ACTIVITY

Birds must be active. To this end, the personnel working in the sheds must walk slowly periodically in order to entice them to move. When kept permanently lying down, the movement of food is delayed due to the pressure that is produced on the area of the body that is in contact with the litter.

LIGHTING OF THE BUILDINGS

The lights must be on, preventing the chickens from resting.

INTESTINAL TRANSIT

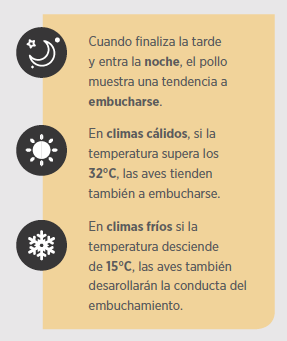

The transit of the food once ingested until the excretion takes between 4.0 and 4.5 hours normally. Thompson, 1993. Consequently, the capture of chickens should start five hours after they have been fed. It is important to keep in mind that there are special environmental conditions that affect the successful evacuation of the intestinal tract-Dr. Julie Northcutt of the University of Georgia, USA, 1997-

In order to reduce the weight losses that occur during this stage, in many companies a kind of serum is supplied to the birds. It seems that with this action, the decrease has been reduced by up to 0.5%. Under normal conditions, this dehydration process varies between 1.5% and 2.0% for approximately 3.0 hours.

TO CONTINUE READING REGISTER IT IS COMPLETELY FREE

Access to articles in PDF

Keep up to date with our newsletters

Receive the magazine for free in digital version

REGISTRATION

ACCESS

YOUR ACCOUNT

LOGIN

Lost your password?