Smoked injected chicken hams are now in high demand all over the world, as it is a product with good texture, flavor and juiciness.

- In addition, they stand out for their added values in flavor, color, appearance, consistency and for having a longer shelf life compared to fresh chicken.

- For the preparation of this ham we will select the boneless breast.

In this article, we will discuss the formulations and processes of this tasty product, which is formed in molds and cooked from boneless chicken breast, which has been previously stripped of the skin and cleaned of excess fat and connective tissue.

CHICKEN MEAT RECEPTION

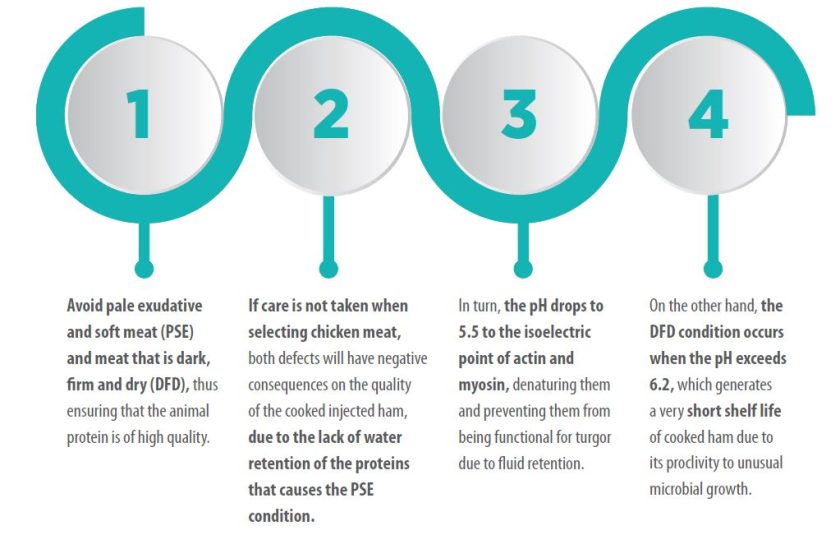

At the reception of chicken meat, it is important:

MEAT STORAGE

We must ensure the correct storage of meat by verifying the records of the temperatures to which it has been exposed.

- If the meat is received frozen, it must be thawed to 2°C.

- Ideally, it should have a pH of 5.8, but 5.6 to 6.1 is acceptable.

BRINE INJECTION PROCESS

The chicken meat must go through a brine injection process with perforated needles with sufficient pressure (1.5-2.5 bar) to distribute the brine in the maximum possible points of the meat for adequate distribution and retention of the brine by the chicken meat.

- The brine incorporates those ingredients that give the ham, organoleptic characteristics such as flavor, aroma, color, texture, consistency, juiciness and also a yield that will have a favorable impact on the cost of ham production.

Among the brine ingredients we will use are, to name a few:

- Sodium erythorbate is an antioxidant and color fixative.

- Ascorbic acid (which stimulates color and prevents oxidation of meat myoglobin).

- Sodium Tripolyphosphate (which restores moisture retention functionality to meat protein).

- Sodium lactates and sodium di acetate as bacteriostats to prolong the shelf life of the ham.

- Dextrose to disperse the powdered components and to balance the flavor of the salt.

- Salt, as a flavoring agent, retains water and activates the meat protein, thus having a similar effect, but to a lesser extent, than phosphates.

- On the other hand, in order to stimulate meat flavors, seasonings are used either from pure spices or from oleoresins.

- Nitrites are used for meat curing and monosodium glutamate can be used optionally to stimulate flavor.

In the formulation, we will incorporate the options at hand and thus take advantage of them for the preparation of the brine, taking into account that the powdered condiments should be easy to dissolve in water.

In this case, I suggest that they be seasonings with a tradition of consumption in each country or region where the ham is to be sold.

SALT CONTENT

The salt content of such seasonings must be considered in order to perform the balance of salt, curing salt or salt with nitrites.

- In this sense, nitrites are essential to give ham an attractive pinkish-meaty color in the reaction of nitrites and myoglobin, and also generate aromas and flavors of cured meat.

- In turn, it prevents the growth and proliferation of Clostridium Botulinum, which is a sporulated bacterium that can cause food poisoning.

INGREDIENTS AND BENEFITS

Let’s take a look at the ingredients and their benefits to ham:

SMOKE:

- It provides one of the essential characteristics of ham.

- It can be used in powder or liquid form and is made by extracting the essence of wood from very well-defined species such as walnut, oak or apple tree, among others.

CARRAGEENANS:

- They are made from seaweed and have a high water retention capacity and gel at cooking temperature, generating a pleasant consistency and improving the slicability of the ham.

- This is important for the visual quality and also for the slicing yields associated with the costs.

ISOLATED SOY PROTEINS:

- They are very functional for stable water retention and provide protein content at a lower price per protein point than meat, improving costs.

MILK PROTEINS SUCH AS CASEINATE:

- They are very functional proteins for water retention and provide a very pleasant flavor to the ham.

PLASMA PROTEINS:

- They have an important water retention capacity and provide good slicability to the ham.

POTATO STARCH:

- It is one of the cheapest extenders for ham and care should be taken to stir the brine frequently to avoid precipitation.

- My suggestion is that for better ham quality, the use of starch should be used in low percentages and the country’s regulations should be checked to see if it is permitted for use in ham production.

CORRECT CALCULATION OF COMPONENTS

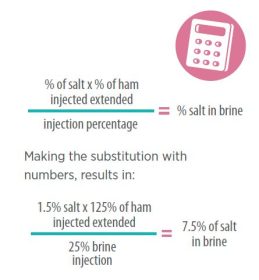

In order to make a correct calculation of the components of the formula, a mathematical operation must be performed. We will take salt as an example, which we will use in this formulation at 1.5% with an injection of 25%.

With 7.5% salt in brine injected at 25% in the ham, we will have 1.5% salt in the injected ham. This calculation should be made for each ingredient and, in this way, we will obtain the quantities to be used in the brine and calculate the quantity of water.

We must make an operation of 100 minus the sum of all the ingredients.

- As an example, in a brine with 15% of ingredients, the following operation should be carried out: 100 – 15 = 85% water or water and ice.

- In this case, a suitable proportion is 75% water and 25% ice, which corresponds to the water in the brine to maintain a temperature below 2°C.

- If the water is cold, the percentage of ice will be less than 90-10 or 95-5 (90% water and 10% ice).

- The brine should be in the range of 7 to 9 with respect to its pH.

When the ingredients are dissolved in the brine, injection is carried out in the injector by adjusting the pressure and speed of the belt to obtain 25% injection. About 10 kg of chicken are weighed and the injection and calculation of the injection percentage is carried out.

- When the injector is adjusted, the injection process is performed in a single pass through the injector.

- After injection, the brined chicken meat should be placed in a cold chamber at a temperature of 0 to 2°C for 12 to 24 hours.

- After resting, the injected chicken meat with the small surplus of brine (injection loss) is passed to the tumbler (or massager) where only 2/3 of the equipment is filled to obtain a good evolution.

- In addition, the temperature of the massager should be at 2°C to 5°C. In this way, the protein can be extracted efficiently and gradually so that the brine and its ingredients penetrate as homogeneously as possible.

HAM PRODUCTION SYSTEMS

There are two different systems for the production of cooked ham:

1.- Massager

One of them is the massager where the injected loin is dumped in the next program:

- Eight minutes of work with 12 minutes rest.

- The total running time of this program is 10 hours.

- The number of revolutions depends on the diameter of the massager and the guide value of 4 to 8 rounds per minute.

There are massagers that rotate the whole unit (large size) and there are also those where a paddle only rotates inside (small size from 100 to 350 liters).

2.- Massaging systems with a drum size of 1000 to 5000 liters.

- Here, the execution time is 3 to 4 hours non-stop with 4 turns of rotation per minute.

- The advantage is that the machines can be filled almost completely and their production is faster (higher volume in less time). This is a massage system because the meat is rubbed against the meat.

In both systems, the process is carried out under maximum vacuum.

- When the paste is removed from the massager, it goes to the drawing process in plastic casing with a caliber of 110 to 135mm and a length of 1.2 to 3 meters, which are then deposited in molds.

- These are then pressed in multi-mold systems or in simple rectangular or other shaped molds.

- The molds are placed in pots and cooked at 80°C in water that covers all the molds.

- When the temperature reaches 72°C at the coldest point of the ham, they are removed and cooled with fresh water until it reaches 35°C.

- These are removed from the mold and transferred to a cold storage room, where they must be cooled to 2°C to 4°C before being sliced or sold whole.

In this article, we have addressed the most important points for the production of formed injected chicken hams, considering all stages of the process with technical advice. Likewise, industrialists have within their reach information to develop a line of hams with a very important impact on the local or regional market and, in this way, strengthen the diverse offer of quality sausages with competitiveness.

PDF