Content available at:

Español (Spanish)

Poultry facilities, as we already know, must comply with set requirements with respect to hygiene and animal health, with the ultimate objective of guaranteeing the safety and quality of their productions.

To meet said objectives, it is essential to carry out a good cleaning of the facilities and their subsequent disinfection.

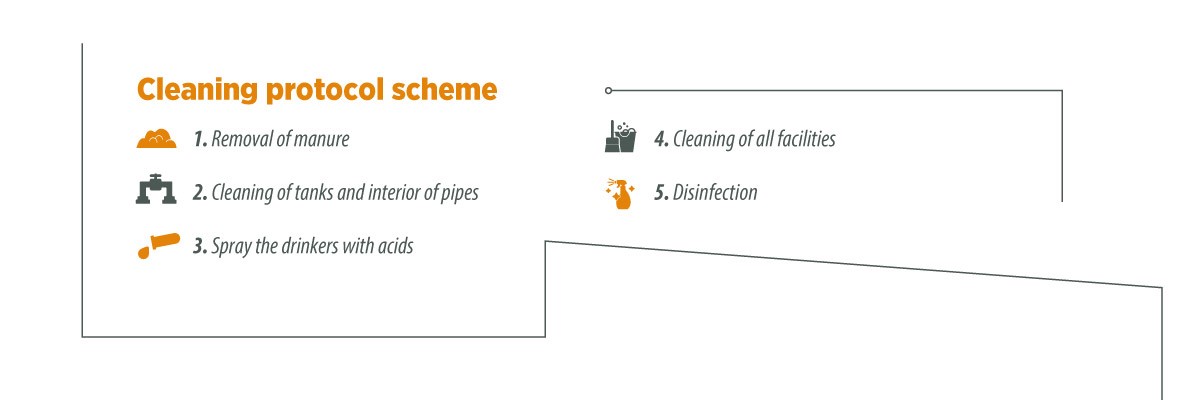

Cleaning must be divided into a series of steps, and it’s essential to be very mechanical, so that no dirt or debris are left behind.

Cleaning protocol scheme

From my personal and professional experience, we have been trying to optimize our protocols, with the aim of trying to reduce time as much as possible, while maintaining efficiency.

The first step that must be carried out is the removal of the manure, which must be done in the first 24 hours once the birds have been removed. This is crucial in the fight against alphitobius (beetles). Once the manure is removed, we should sweep or at least blow through the buildings to eliminate a lot of the organic matter. This will greatly facilitate the cleaning of the floors.

Secondly, we must carry out the cleaning of tanks and interior of the pipes, for which we must consider what products to introduce during an active flock, since if we previously used acids, we should look for a basic product for cleaning, as the biofilm that will be produced will be acidic. In order to save time, we can carry out this step right before the removal of manure, thus allowing the product to take effect while we carry out the other actions.

Depending on the area where the farm is located, and the quality of the water there, it is very common that just before cleaning of the facilities begins, we spray the drinkers with an acid solution (several in the market), to eliminate limestone build-up caused by hard water. We must then rinse these drinkers after 20-40 minutes in order to avoid their deterioration.

Once all the above steps are done, we can proceed with the cleaning of the facilities.

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón