Scalding tank

29 Apr 2020

Reduction of Salmonella contamination during processing

Content available at: Español (Spanish) Português (Portuguese (Brazil))Problems with litter quality and the use of foggers to combat heat can […]

Content available at:

Español (Spanish) Português (Portuguese (Brazil))

Problems with litter quality and the use of foggers to combat heat can cause birds to become wet and dirty with litter and droppings, which can create a severe contamination problem during the processing as there is a large amount of organic matter in the scalding tank.

The scalding tank is one of Salmonella’s most critical contamination points in any plant. Most of these tanks do not have a true counter-flow of water.

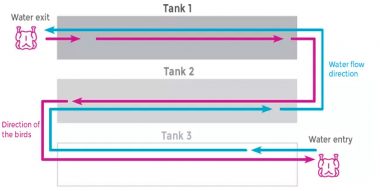

Figure 1. Substitution of multiple blanching tanks to dilute organic matter

The water must flow against the direction of the carcasses to wash them effectively. The water flow must be abundant to dilute the organic matter in the tank effectively. A good practice is to install multiple scalding tanks in sequence to dilute the organic matter as much as possible, as illustrated in Figure 1.

The objective is to minimize the amount of organic matter entering the chiller, where the efficiency of an oxidizing agent such as chlorine is drastically reduced as organic material increases.

Paradoxically, removing organic matter from contaminated birds increases the carcasses’ contamination because the removed organic matter contaminates the water in the scalding tank. Therefore it creates an opportunity for cross-contamination.

The use of multiple scalding tanks is very important to reduce contamination.

Some companies reduce the scalding tank temperature from approximately 130°F to 100-110°F. This practice is counterproductive because it encourages organic matter to sink to the bottom of the tank, facilitating contamination with Salmonella, which lives and even multiplies at 100°F.

Microbiological evaluation of the scalding tank is critical to determine if it is a high-risk point for Salmonella contamination. An example of a scalding tank not operating correctly is illustrated in Figure 3. Possible reasons for this problem include tank temperature being too low, insufficient water supply, and water flowing in the same direction as the carcasses instead of a counterflow

Figure 2. Scalder operating as a bath and not as a counterflow station

Older scalding tanks do not have a reverse flow of water, which is the worst situation for Salmonella control. The situation is aggravated when the processing plant has water supply limitations.

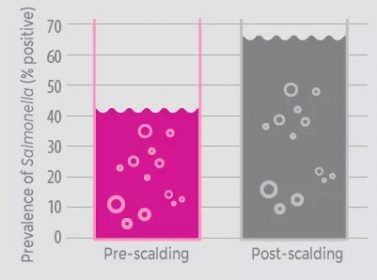

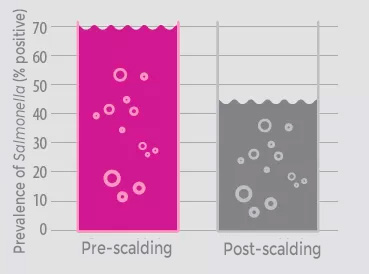

Figure 3. Scalding tank with the inadequate operation and where Salmonella contamination increases as the carcasses pass through it.

Correcting the problem

This problem can be corrected by one or more of the following actions:

- Establish a counter-current water flow

- Ensure a water temperature of at least 123 ° F

- Install a chlorine shower and brush system immediately after bleeding to remove excess stool before scalding

- Consider introducing a chemical into the tank

Once these corrections are implemented, it is important to conduct a new microbiological evaluation. Figure 4 illustrates a realistic scenario in a properly operating process plant.

Figure 4. An adequate functioning scalding tank reduces contamination between before and after carcass scalding.

In conclusion, the scald is crucial in implementing interventions that allow effective Salmonella control, especially when microbiological evaluations show that the scalding tank is a major risk point.

A survey conducted by the United States Poultry and Egg Production Association (USPEA) revealed that approximately 50% of companies use chlorine in the tank, and the other 50% use sodium hypochlorite.

Neither of these products is effective because chlorine is immediately inactivated upon contact with organic matter. Also, sodium hypochlorite does not significantly impact bacterial contamination levels.

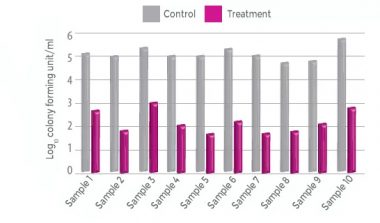

Figure 5. Effect of a chemical to sanitize scalding water (reduction of aerobic bacteria)

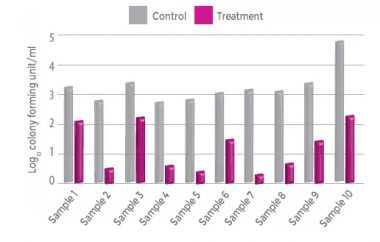

Figure 6. Effect of a bacteriological index reducing product on the concentration of E. coli (colony forming units) detected in carcasses immediately after scalding.

Figures 5 and 6 illustrate the concentrations of bacteria before and after the blanching when using water without chemicals and when using products to reduce the bacteriological index.

The addition of an acidic disinfectant can be considered, which allows the water temperature to be reduced, although it has a tremendous impact on the efficiency and cost of scalding.

Benefits of using chemicals in the scalding tank

When chemicals are used in the scalding tank, it becomes possible to reduce the water temperature, which can generate the following benefits:

- Feather removal is facilitated (when water is acidified)

- Less bacterial growth, including Salmonella

- Fewer over-scalding problems, especially in the breast muscle

- Less energy cost to maintain the temperature of the scalding tank

- Less overcooking of subcutaneous fat, allowing better yields

The rubber fingers of plucking machines represent one of the most significant cross-contamination risks in processing plants. They come into direct contact with contaminated surfaces and the rest of the carcasses.

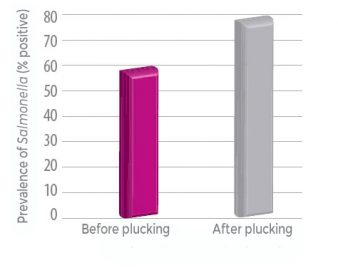

Research carried out at the University of Georgia has determined that the water that accumulates in the bottom of these machines can easily contain up to 1 million bacteria per milliliter, even when using water with a chlorine concentration of 40 ppm. Figure 7 shows the increase in salmonella prevalence during plucking.

Figure 7. Salmonella prevalence before and after plucking

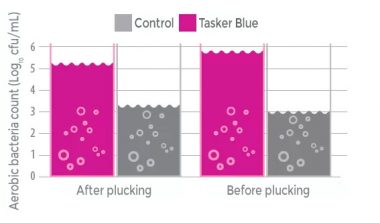

Figure 8 illustrates the data resulting from evaluations made in scalding tanks, pluckers, and New York type spray stations, where chlorinated water (controls) or the product “Tasker Blue” were added. The effects were critical as adding “Tasker Blue” resulted in a 2.7 log10 decrease (more than 99%) of bacteria on the carcass surface upon arrival at the re-processing station.

Subsequent studies have shown that this action also dramatically reduces salmonella in carcasses as they exit the chiller.

Figure 8. Aerobic bacteria count before plucker and after pre-processing station.

A significant problem regarding using chemicals in the scalding tank or plucking machine is that managers are not used to investing at any point “at the beginning of the process,” but more towards the end. At the beginning of the process, the managers’ investment can change rapidly as the legislation changes regarding permissible Salmonella contamination levels.

There are three general methods to reduce pathogenic bacteria in the processing chain except:

- Scalding tank

- The plucker

- The cooling system

- Post-Cooling Immersion Systems

Showers

Purpose

The purpose of this equipment is to wash and sanitize the processing equipment that comes into contact with the carcasses so that contamination is not transferred to other stations and that cross-contamination between carcasses is reduced. It is important to have high water pressure and add chemicals such as chlorine. Additionally, chlorine dioxide, peracetic acid, or products such as Zentox or TOMCO (acidified hypochlorous acid) can be used.

Cl Effectiveness

An important limitation to the effectiveness of chlorine is the accumulation of fat or other organic materials on the equipment, which prevents the penetration of the product so that it can destroy bacteria. The bacteria are easily released when they contact the carcasses, which can easily happen with equipment such as brushes dedicated to removing fecal matter after evisceration.

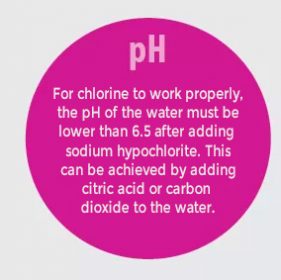

pH in washing systems

The pH of all washing systems should be kept below 6.5. A quality program should be in place to frequently check the acidity of the water if good control over bacterial contamination is to be maintained. Shower pressure should be checked, and it should be ensured that spray nozzles are not clogged.

Figure 9 illustrates some sprinklers that are not working and others with a very irregular water distribution pattern. Sprinkler nozzles should be positioned to wash the surface of the equipment that comes into contact with the carcasses and the carcasses themselves.

Figure 9. Malfunctioning washing equipment.

Showers for washing inside & outside the carcasses.

These showers should be checked frequently for their levels of:

- Chlorine

- The concentration of other products

- Chemicals

- pH

- Water pressure & distribution

General recommendations for washing stations

Some general recommendations for these washing stations include:

- Maintaining the water pressure.

- Maintaining the correct pH level.

- Maintaining the proper concentration of chlorine or any other chemical.

- Maintaining the adequate distribution of water on the carcasses.

Several chemicals that are being experimentally tested for this purpose include:

- Chlorine dioxide

- Peracetic acid

- Zentox & TOMCO (acidified hypochlorous acid)

Most companies use chlorine in washing systems.

A study conducted by Northcutt et al. –USDA / ARS 2005– suggested that the addition of chlorine to the internal and external washing showers of the carcasses does not have any positive effect on aerobic bacterial counts of E. coli, Salmonella, or Campylobacter on carcasses, since in many circumstances Chlorine is unable to penetrate organic matter if it is too abundant on the carcasses.