Equipos e instalaciones

Navarra relies on COPILOT System to create the ideal environment in its chicken warehouses

Para leer más contenidos de aviNews España

Equipos e instalaciones

Para leer más contenidos de aviNews España

We move to Lezaun in the Community of Navarra, 38 kms from Pamplona, to visit new facilities for the production of broilers equipped with the most advanced and efficient technology offered by COPILOT System, and installed by its distributor in Roberto Martínez, of Eulate Electrical Services. Roberto Martínez is recognized for his professionalism, seriousness and quality of the service offered to his clients.

In Lezaun we find numerous warehouses dedicated to the fattening of chickens, where many of them have in common, having counted on COPILOT System materials for its operation , thanks to the commitment, the individual advice, the value for money and the 20 years of experience offered by this poultry equipment company where comprehensive projects for the complete management of the farm have become their hallmark and quality.

COPILOT System offers comprehensive solutions for environmental management, providing the poultry sector with a complete range of innovative systems for modern poultry farms.

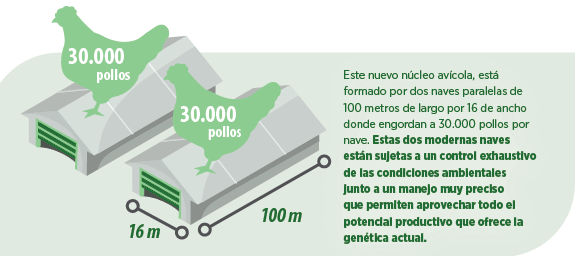

ENVIRONMENTAL EFFICIENCY IN THE NEW FACILITIES OF THE OTXANDORENA BROTHERS

During our visit to Lezaun, we visited the new facilities for the fattening of chickens by Iker Otxandorena, a young poultry farmer who has spent many years dedicated to the fattening of chickens , first in his mother’s ship and then with his own modern facilities equipped with materials offered by COPILOT System.

Iker Otxandorena wanted to stay and live in his village , but with the old chicken fattening facilities left by his mother once she retired, he didn’t have it easy, so he didn’t hesitate twice and looked for a way to base his life in a poultry production that allowed him to continue living where he had always done it.

CLIMATE CONTROL, THE KEY TO THE OPTIMAL DEVELOPMENT OF ANIMALS

As the control of the environmental parameters of the farm is key to obtaining the perfect development of the animals and guaranteeing their well-being, Iker Otxandorena wanted the automation of the environmental regulation to be able to offer his animals a bed in optimal conditions during the whole breeding and an unbeatable environment in terms of temperature, humidity, limitation of the presence of dust and toxic gases and absence of excessive air currents.

COPILOT System proposes different environmental control systems depending on the climatic conditions of the place, the dimensions of the ship, the species and the productive objective, and Iker thanks to its advice, incorporates in its new facilities the Webisense, the automaton of control capable of managing each and every one of the necessary parameters so that the environmental conditions are ideal.

“In my mother’s ship we had an environmental control computer, but it was very old. Now with this new computer offered by COPILOT we have everything under control. In addition, we have not been much of computers, but it is really intuitive, and easy to use, it is designed to make things work well on the ship.

It is an indispensable tool to guarantee productions. The truth is that we are very happy with its operation, and we can consult it from the mobile when we are at home “

TRANSVERSAL VENTILATION, PRECISE DIRECTION CONTROL, AIR VOLUME AND SPEED

These two new ships, have transverse ventilation, easy to use and optimal system for temperate climates or harsh winters. In these ships, the renewal of the interior air is achieved from the depression created by the extractors located on one side of the ship and the air inlets located on the opposite side.

“We value the different types of ventilation to be installed, but taking into account the climatic conditions of our valley and the recommendations of COPILOT, in the end we decided on a transversal ventilation. In addition, in our mother’s chicken house, we were already working with transverse ventilation and we were used to its handling ”.

OPTIMIZATION OF THE FOOD AND WATER RATION DISTRIBUTION

For a correct management of feed and water it is essential to have a fully automated distribution system. The COPILOT System regulation centers also allow the possibility of establishing time programs for the distribution of water and food (rationing) while monitoring consumption.

Good food management, understood as a good selection of equipment and proper management of food distribution, has a high impact on the quality of the productive results and economic benefits since we obtain the optimization of food efficiency, improve the batch uniformity while minimizing seizures in slaughterhouses.

The feed must be distributed so that all the birds can eat at will or according to the ration established by the producer or the integrator. The distribution system must guarantee a constant renewal of the feed to prevent it from rusting or becoming damaged.

“We carry three fattening in these ships and we are really satisfied with the results. We can compare the results of my mother’s old ship with the results offered in these new facilities and the truth is that the difference is very noticeable. Providing the installation of the best materials and the best technology changes your vision of the profitability of poultry farming since we now work clearly at another level ”.

In the ships they have incorporated the Multibeck® feeder offered by COPILOT System. This feeder has a design that prevents the entry of the chicks in the feeder , thus avoiding contamination by dejections and loss of accessibility to the food.

In addition, it presents a shallow dish that favors the access to the food to the chick from the first day of life , avoiding at the same time the waste of feed. Also, its studied design facilitates the circulation of birds around the feeder, reducing shocks and avoiding the barrier effect.

The Multibeck trough has a design that facilitates cleaning and disinfection with an exclusive rotation system that allows access to the inside of the trough in high pressure washing.

“In the sanitary void we also realized the enormous quality of the materials and the importance of the design of the trough. It is very easy to clean and is very resistant. ”

HEAT RECOVERERS, TO REDUCE HEATING COSTS AND IMPROVE ENVIRONMENTAL CONDITIONS

In these two new ships, we also find the COPILOT IC10 heat recuperators, incorporated as another element of the ventilation system, which brings about a reduction in heating costs and an improvement of the environmental and sanitary conditions of the ship.

“The energy savings offered by the heat recuperator together with the quality it offers to the animals’ bed is very good. Other poultry farmers in the area had already incorporated it and recommended it to us, so we didn’t doubt it much when incorporating it. ”

These heat recuperators take advantage of the heat given off by the air they extract from the ship to heat the clean air they capture from the outside, avoiding cross-contamination.

With this exchange, fuel is saved in the heating and an ideal bed is achieved especially at the start of the fattening when the temperature setpoints and their difference with the outside are higher

“We have seen the ship working in summer and winter and we are very satisfied with the management done by the Webisense computer. The quality of the bed is very good until the end of the fattening and this is due to the excellent work of the climate control computer and the heat recovery at startup. ”

So good Iker is doing on his ship, that his brother Ion will join the poultry industry also in a third ship that they already have in mind. So good is Iker doing on his ship, that his brother Ion will join the poultry industry also a third ship that they already have in mind “the idea in the future is to make a new ship and that my brother also joins the farm. Between the two, we will take the installation and we can better manage the free time. ”And that my brother also joins the farm. Between the two, we will take the installation and we can better manage the free time ”.

ION DÍEZ DE ULZURRÚN, A NEW AVICULTOR WHO WANTED TO HAVE THE BEST TECHNOLOGY

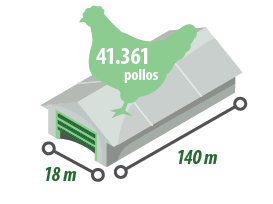

On the day of our visit to the idyllic Lezaun we also met with Ion Díez de Ulzurrún, a new poultry producer recently incorporated into the sector.

“I wanted to stay in town and for that I needed a business that offered me quality of life. My parents have pig farms, but the pig waste management and the level of profitability and technology in poultry farming made me opt for the latter when it came to making a living. ”

Ion is 24 years old and has also found a noble way of making a living in poultry farming. “We got in touch with the integrator and from there we began the procedures for the development of the project. We have also researched in several facilities to find the one that we like the most. The materials offered by COPILOT System had very good recommendations from our neighbors in the valley: If you are looking for quality and efficiency, bet on COPILOT, they told us ”.

The new Ion ship is 140 meters long by 18 meters wide and also has transverse ventilation, heat recovery, cooling cooling and the WEBISENSE regulator offered by COPILOT System.

On the day of our visit, their chickens had 31 days of fattening and the atmosphere that was breathed on the ship was ideal “it is my first fattening and I am very happy. The chickens are getting fat and the atmosphere that is breathed inside the ship is fantastic. Right now I have my first 41,361 chickens almost ready to send to the slaughterhouse. ”

Ion tells us that since COPILOT they have offered him a lot of advice and they have accompanied him in everything “I felt that they were also part of this project and when you start this it is appreciated”

COPILOT System has become the safest and most reliable option for carrying out poultry projects, guaranteeing optimal production results.

COPILOT System offers advice before, during and after the completion of the work, always walking hand in hand with its customers.