Exhaust fans for big environments play a crucial role in air exchange and the elimination of moisture and odors in agricultural barns.

In agriculture, various types of exhaust fans exist, differing in their operational details, including the opening mechanisms of their shutter blades.

In this article, we will explore the two main opening systems:

Analyzing their advantages and applications, with particular attention to the patented systems by Termotecnica Pericoli.

THE CENTRIFUGAL SYSTEM

The centrifugal system is widely used in exhaust fans for livestock and agricultural applications.

This system harnesses the centrifugal force generated by a motor to open the shutter blades and allow airflow. A mechanism connected to the fan converts the centrifugal force resulting from rotation into linear force, causing the opening of the shutter.

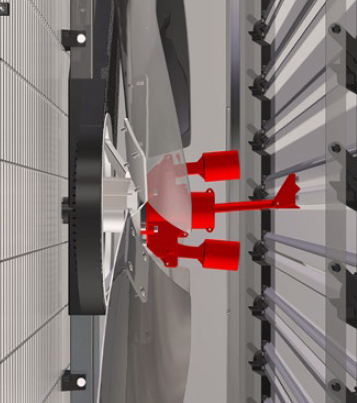

Termotecnica Pericoli, for its EWS fan, designed and patented in 2001 an opening system called the “Omega System” that operates on a different principle:

This innovative design results in a drastic reduction in repair and maintenance costs compared to other options on the market.

Energy Efficiency: The centrifugal system can be highly energy efficient, as the generated centrifugal force is utilized to open the blades, reducing consumption compared to a solution involving a servo motor.

Operational Efficiency Improvement: The EWS system operates reliably, enhancing overall fan performance. Whether at variable or fixed speeds, it ensures optimal operation and allows the fan to be used in speed modulation.

Reliability: Centrifugal systems tend to be robust and reliable in the long term, requiring less maintenance than other solutions. The reduced number of components avoids tolerances in assembly that could create abnormal movements in the system leading to long-term damage.

Attention to Detail: High-quality materials and oversizing of components are used to withstand all possible forces the system may be exposed to.

Single Integral Unit: The unique design of the device results in a perfectly isostatic structure during fan operation, creating vibration-free and balanced system operation.

Silent Closure: Unlike other options on the market, the EWS opening system operates silently, minimizing interference with animals and operators.

Free Airflow: The compact design of the system minimizes obstruction of airflow, ensuring high air displacement and thus high fan efficiency.

Handling and Transport: The compactness of the system results in a fan housing wall width of only 400 mm, maximizing loading possibilities on trucks and in containers.

THE FLAP SYSTEM

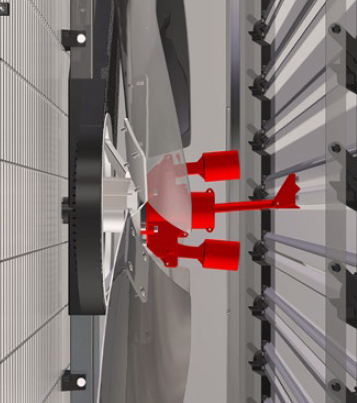

The Flap System is an alternative to the centrifugal system and operates slightly differently. In this case, the shutter blades are connected to an element that serves simultaneously as a flap and as a counterweight.

When the air inside the exhaust fan reaches a certain velocity, it behaves like a flap, pushing outward, opening the blades and allowing airflow.

In 2006, Termotecnica Pericoli’s R&D department introduced and patented an innovative shutter opening system called the “Flap System” installed on the EOS exhaust fan, refining the historic counterweight system and combining its advantages.

Its peculiarity lies in its basic use of the principle of gravity, but the particular design of its flap balances the weight of the blades and the force of the air to ensure optimal opening of the shutter, even at high internal pressures.

ADVANTAGES OF TERMOTECNICA PERICOLI’S FLAP SYSTEM

Simplicity: The physical principle driving the mechanism is simple, as is the system itself, which uses basic components.

Reliability: It can operate for long periods and guarantee shutter opening even in demanding conditions.

Low Susceptibility to Wear: Unlike other mechanisms, moving parts subject to breakage over time are minimized, making it a long-lasting product.

Guaranteed Performance: The EOS opening system operates even with particularly dirty fans. In rather aggressive environments (such as poultry farms), the shutters may struggle to open because the weight of the dust on the blades can strain the mechanism. The flap designed by Termotecnica Pericoli always evenly distributes weight in the system, functioning correctly as a counterweight and ensuring the opening of the blades even in particularly hostile conditions.

Perfect Protection from Light and Air: Thanks to the side gaskets, the blades close completely without allowing light, air, or dust to filter through.

EOS marked a turning point for Termotecnica Pericoli, opening doors to the global market thanks to the intuition and ingenuity of the technical department. Even today, albeit with the necessary updates, it is one of the most appreciated (and often imitated) products in our entire range.

The two shutter opening systems of EWS and EOS are the result of careful analysis and listening to the needs of international customers and farmers.

The ingenuity and diligence of the Research & Development department have succeeded in designing and patenting innovative and efficient solutions that are reliable both when operating at variable speeds and under high internal pressures.

For more information, visit our website or email us at [email protected]

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón