Content available at:

Español (Spanish)

Mitigating the microbial risks of the production chain is essential to guarantee the safety of the feed destined for the animal and, therefore, the human consumption of animal protein.

Feed contamination can occur at any production stage, from raw material transportation to storage during production on the processing line or the farm.

When conditions for microbial growth are optimal, Enterobacteriaceae such as Salmonella can become a significant threat to the quality and safety of the finished feed and consequently a threat to birds and humans. Salmonella is an example of this type of threat, difficult to detect in routine checks, as it can enter a lethargic state, leading producers to the erroneous conclusion that raw materials for feed and production lines are free of the pathogen.

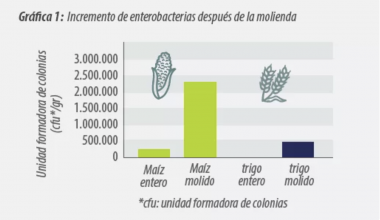

Activation of lethargic Salmonella and other Enterobacteriaceae can occur due to higher temperatures and water activity levels. This can happen at any production stage, such as during raw material storage, milling, or production breaks. These changes allow the metabolism of microorganisms to reactivate and proliferate. In addition, as the milling process passes, the nutrients become more accessible to the Enterobacteriaceae, enabling their entry, multiplication, and triggering cross-contamination throughout production.

Graph 1 shows the increase in the colony-forming units of Enterobacteriaceae before and after grinding.

When microorganisms are present and the accessibility of nutrients increases during milling, a degradation of nutrients also begins. This implies that microorganisms consume the nutrients and reduce their availability to the animal, resulting in a decline in production efficiency. For example, a study conducted by DiConstanzo in 2009 established that the average weight loss of corn due to nutrient degradation caused by microorganisms is 7% (DiCostanzo, 2009).

Several solutions can contribute to the reduction of risks and growth of Enterobacteriaceae, such as Salmonella. The most common solution is the hydrothermal treatment used in different production processes. The hydrothermal treatment consists of adding heat and humidity to the feed before pelleting. In Graph 2, you can see the impact of adding humidity above 100 degrees Celsius on the colony-forming units of Salmonella.

However, to ensure the successful reduction of

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón