Content available at: Español (Spanish)

It is a mechanical process of fragmenting liquids into droplets, but the key lies in how to evenly distribute them. Some techniques of spraying include:

- Hydraulic spraying: Put the liquid under pressure, making it come out through a calibrated hole or nozzle

- Pneumatic Spray: Place the liquid in a high speed air stream

- Centrifugal spraying: Subjecting the liquid to the reaction forces generated by a rotating element

By combining the process of drop formation with the technique used to transport it to the target, it is also possible to classify the sprayers. In the hydraulic system (the most used) the formation of the drop is made by the pressure of the liquid and its transport by the kinetic energy that is produced.

The water to dilute the vaccine must be completely free of sanitizers with an added stabilizer and at a temperature between 18 – 25 ºC.

The mouthpiece is one of the most important elements for carrying out spray vaccination. They are parts that have calibrated holes for vaccine release. By changing the nozzle and the working pressure, you can get drops of different sizes and flow rates.

Nozzle functions:

- Volume: Determines the applied flow

- Quality: Produce drops of a certain size

- Uniformity: Proper distribution of the vaccine

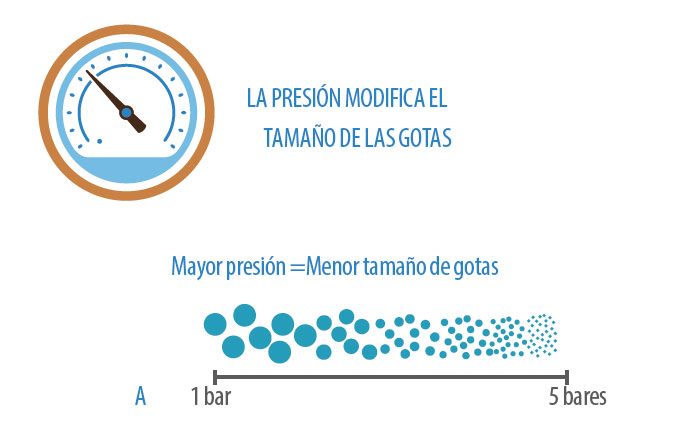

Figure 1 . Modification of the drop diameter according to the pressure

The nozzles used for spray vaccination are adjustable. The most commonly used are variable cone nozzles, because when the body is rotated, the spray angle varies from a narrow jet with large drops to a wide cone with small drops.

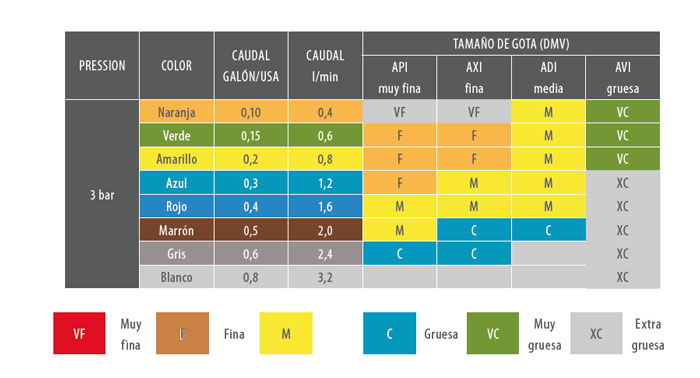

The identification of the nozzles is carried out in accordance with the ISO standard, through a color code and / or through numbering. These specifications are defined for flat fan nozzles at a nominal pressure of 3 bars – Table 1-.

Higher pressure not only increases the flow rate of the nozzle, but also influences the size of the droplets and the wear rate of the holes.

Table 1 . The identification of the nozzles according to the ISO standard -through a color code and / or by means of a numbering-

OBJECTIVES TO BE FULFILLED BY A GOOD VACCINATION DEVICE

DROPLET FORMATION

A spectrum of drops between a maximum and a minimum defined as adequately as possible and according to the type of vaccination to be performed should be sought.

DROP TRANSPORT

It must emit a spray according to the type of vaccine to be used and it must also deliver the drops with enough energy to ensure effective penetration.

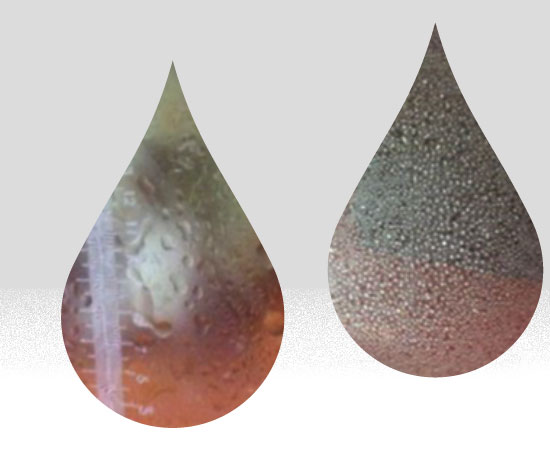

Figure 2. Before and after the installation of a vaccination kit with conical spray nozzles for vaccination in hatcheries.

Spray must be produced with droplets that are large enough to avoid loss by evaporation or drift.

In addition, they must be small enough to produce good coverage on the target, i.e: not less than 60 microns for adult birds, 100 microns for young birds, and up to 300 microns for hatchery use.

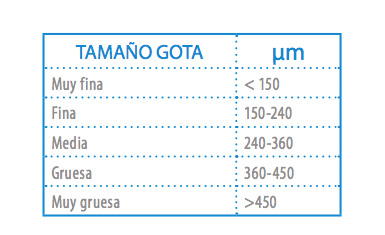

The spray profile is made up of numerous droplets of variable size, also known as the spray spectrum. When speaking of droplet size, it refers to the diameter of an individual droplet -Table 2-.

Table 2. Drop size used for spray vaccination based on individual diameter.

When vaccinating in a hatchery, it is necessary to check the dispersion of the drops produced by the vaccine spray on the chick tray. For this purpose, a droplet verification tool is used, which allows the evaluation of the dispersion -Figure 2:

- Coverage of the vaccine solution in the chick box

- The uniformity of the vaccine solution, that is, whether or not there is homogeneity in the drop size.

Carrying out this test allows us to check if we have forgotten to review the proper maintenance and correct calibration of the nozzles, to determine the uniformity of the flow rate and the wear and tear over time and their use.

Steps to determine the uniformity of flow and wear (hydraulic spraying):

- Measure and record the flow rate L/Min of each nozzle. It should be done at normal working pressure with a flowmeter.

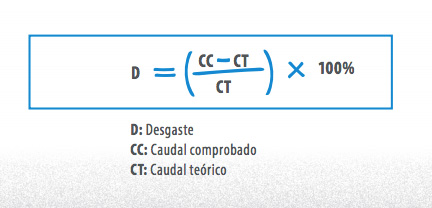

- See the uniformity. The flows are added and the average flow is calculated. Nozzles with a deviation of + – 10% must be replaced.