Content available at: Español (Spanish)

Feed cost is of significant importance in animal production, since it represents around 70% of the cost of live animals or derived products. Therefore, maximizing the use of feed, improving the productive efficiency index by improving feed conversion and reducing the negative impact of microorganisms, is essential for economic and environmental viability. One of the ways to improve this efficiency is through heat treating the feed.

The objective of this article is to indicate some referential parameters of operation for the different processes, with an emphasis on pelletizing, expansion and for formulas classified as having high starch content (broilers and fattening pigs), in order to improve the results with the use of these processes.

It is a very controversial topic where doubts and uncertainty appear, both in companies and in the different scientific works available. In addition, there are also several aspects that need to be studied in greater depth. However, here we will try to offer some practical and operational guidelines.

Main variables worked in heat treatments:

These variables can be worked with different correlated intensities and will basically depend on the type of feed treated, the defined objectives and the structure of the processes.

Main heat treatments used in the manufacture of balanced feeds:

Thermo-conditioning: Heat treatment without physical format change. It consists of heating the feed, generally via indirect heat; and its basic objective is to sanitize it, that is, to reduce or eliminate microorganisms. More often used for poultry breeders and commercial layers in order to maintain the grain size advantage.

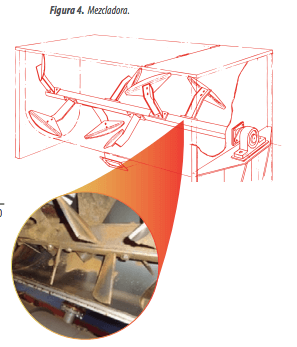

Pelletizing: It is the most widely used process in the feed industry, especially for economically exploited animals (pigs, poultry, cattle, …). In this process, the powdered feed is transformed into granules (pellets). It is the best known process and where there are fewer doubts about economic and operational viability.

Expansion: This process uses the variable pressure with greater intensity and is normally used as a conditioning intensification process in pelletizing lines. It is also used to heat treat (expand) individual or joint products such as corn, soybeans, wheat, cakes, etc.

Extrusion: It is the most complex process and works the variables with greater intensity. Depending on its cost, it is generally not economically viable, except for pet and fish food.

Main Objectives of Heat Treatments:

- Physically alter the food: transform the powdered feed into granules of various formats. Facilitates intake, making food more attractive, generating less waste.

Referential specifications for physical quality (see below).

- Chemically / bromatologically alter the nutrients so that granule formation is possible in a stable way and also to improve digestibility. Three actions are sought:

Starch gelatinization: (Pelletization 20 to 35%, Expansion 40 to 70%). Despite being less intense in pelletizing, it is decisive for the resistance of the pellets.

Lamination of organic particles. Fundamental to establish strong bonds between the particles.

Permeability of cell walls. Facilitates the penetration and action of digestive enzymes.

- Reduce / eliminate microorganisms: Referential specifications: Total bacteria and fungi:

Production animals: <10,000 cfu / gr and breeders 1,000 cfu / gr

Enterobacteriaceae: Production animals: <1,000 cfu / gr and breeders 100 cfu / gr of food.

Salmonella free

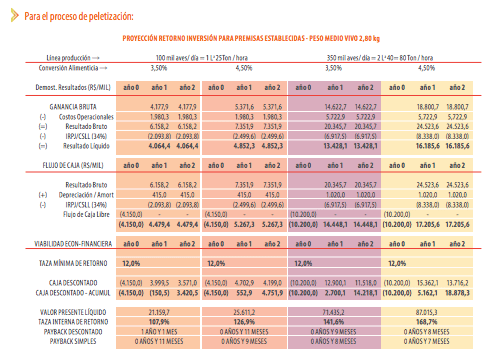

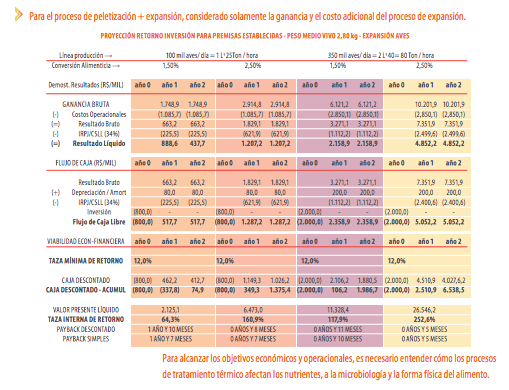

Calculation of the return on investment based on some previously established premises for chickens in Brazil, May 2018

Heat treatments:

Main impacts on food and subsequent processes

Nutrients

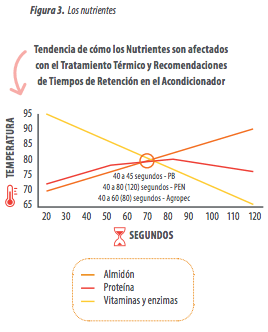

- As a general rule and within the limits recommended for the use of variables in heat treatments, starch tends to improve in digestibility as the variables intensify.

- The protein improves to a certain extent , then stabilizes, and later the risks of excessive denaturation increase.

- Vitamins, enzymes, medications, and other supplements are lost from the start and intensify as the variables used intensify. These damages depend on the type / sensitivity and the protection they present.

Microbiology:

Reduction / Elimination

- General rule: The more intense the use of variables, the greater the reduction in microorganisms.

- Rule of thumb : 40 seconds is enough to eliminate practically all the microorganisms presenting the greatest risks, especially salmonella, since the temperature is above 80ºC (ideal 82 to 85ºC) and the humidity added via steam is at least 3% .

Although in pelletizing the reduction of microorganisms is quite efficient, we still have great contamination risks such as:

Lack or deficiency of a good cleaning and disinfection procedure in long stops of the process. When the stops are greater than 3-4 hours, we must do a complete cleaning and disinfection.

- Poor cooling and drying

- Maintain feed water activity <0.65%, max 0.70%.

- Maintain the difference in temperature pellets x environment <8 ºC, max 10ºC.

- Do not use contaminated air for cooling and drying.

- Restrict access to the heat treatment area.

- Having inadequate equipment / silos / trucks and / or insufficient cleaning and disinfection from the plant to the trough.

Physical Quality

The physical quality of the pellets improves with the intensity of the use of the variables (temperature, humidity, time and pressure).

The physical quality of the pellets depends a lot on the conditioning process . Without good gelatinization and plasticization, good bonding bridges between the particles are not achieved.

The compaction pressure, despite being important, without gelatinization and plasticization, will not cause lasting resistance.

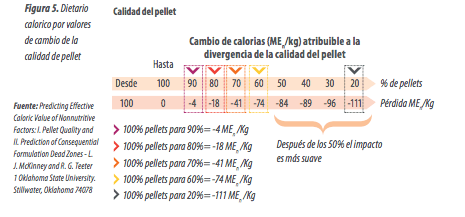

As a general rule, the feed plant should deliver the pellets within a specified physical quality. Based on the literature and some referential standards, we can consider quality pellets:

- PDI (Pellets Durability Index):> 90%. Referential method: Professor Pfost – Kansas University.

- Hardness:

Pigs: + – 2.5 kgf / mm2

Poultry: + – 3 kgf / mm2. Kahl referential method. Others Wagner, Schleuniger, ..

- Pellets or fines percentage: This is the most important indicator, especially for birds. Some references:

Chiller output fine %: <5% (max 8%).

% fine screen output: <5% (ideal 2 to 3%)

- % fine output plant:

With shaker <5 to 6%

Without shaker <8 to 10%.

- % fine in the trough: <30% (that’s what matters)

The important thing is to have enough pellets in the feeder. Based at LJ McKinney and RG Teeter, Oklahoma State University, Stillwater, Oklahoma 74078, at least 70% pellet.

After leaving the plant, the pellets undergo a series of impacts whose intensity depends on the quality of the following processes:

Truck: The impact on the pellets will depend on the type of truck, the handling of the unloading and especially the unloading system. Main types of trucks and unloading systems:

Pneumatic discharge: mainly used in Europe. It practically does not damage the pellets. Increase fines between 1 and 3%.

Mechanical unloading:

- Normal: helical conveyor and without orientation or limitations for discharge: Approximate pellet breakage, depending a little on the resistance: 20-30%.

- Normal with discharge speed restrictions and larger thread diameter: A reduction in rupture can be estimated, in relation to the previous condition, by 5 to 10%.

- Improved normal: with transfer of the products between threads with a hydraulic system, with a conveyor with a larger diameter and speed restrictions on discharge. In this case, the rupture can be reduced between 8 to 12%, in good quality pellets (PDI> 90%).

Transport of the silo from the farm to the feeder.

There is not much academic information on this topic. In practice, based on different evaluations in companies, it allows us to conclude that we can have; depending on the type and degree of automation of the farm, a rupture similar to that registered in the truck.

Final Considerations:

One of the biggest challenges in the compound feed industry, in terms of processing, is heat treatments. Everything indicates that we have great opportunities and at the same time great challenges.

The main opportunities are:

- Improve nutritional quality, seeking the balance between potential gains and risks

- Maintain physical quality until arrival to the feeder

- Eliminate pathogenic microorganisms, without re-contamination in the following processes.

The challenges begin in the project, as physical quality and productivity move in the opposite direction. Therefore, we suggest focus on processes with defined quality and productivity specifications. To produce with quality, it will be necessary to invest in bigger and safer machines, invest in shakers to remove the fines and in the addition of post pellet liquids.

There are still many doubts that need to be studied and scientifically clarified on this subject, which is a challenge for companies, universities and research centres.

Thus, without pretending to exhaust the matter, nor being the owner of the truth and not giving prompt and definitive answers, we hope we have contributed to advance the subject a little more.