Content available at: Indonesia (Indonesian) Melayu (Malay) ไทย (Thai) Tiếng Việt (Vietnamese) Philipino

The United States produces high quantities of soybeans since this oilseed provides more than 50% of all the vegetable oils used in this country.

- The demand for this oil is increasing due to its application in generating biodiesel, and soybean meal is a co-product of this oil industry.

High oleic soybean oil, a product of constant innovation in soy production, is rich in oleic acid, similar to olive oil. This high-oleic oil, with its 75% oleic acid content, is gaining popularity due to its numerous health benefits.

- It offers greater stability for food and processed food producers, functionality comparable to hydrogenated oils, but without the issues of trans fatty acids.

- It also allows the elimination of chemical preservatives such as TBHQ and EDTA, making it a healthier choice for consumers.

High-oleic soybean oil stands out with its three times longer frying life than conventional soybean oil and an oxidative stability index exceeding 25 hours.

- This reduces costs, consumption, and waste and minimizes polymer buildup during cooking.

- Its neutral and light flavor enhances the taste of foods, and its melting properties make it suitable for solid and semi-solid soy butter with pastry applications.

- Moreover, it has a higher smoke point than traditional high-oleic soybean, canola, or sunflower oil, as shown in Figure 1.

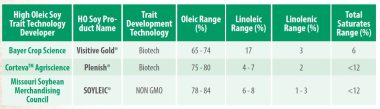

The production of high-oleic soybean oil is poised for significant growth in the coming years, presenting a promising future for the industry. Currently exclusive to the United States, these seeds are backed by a robust system that preserves their origin. The 12 most prominent suppliers of high oleic soybeans or soybean oil are currently using two varieties: the biotechnologically derived Plenish® and the non-genetically modified SOYLEIC® obtained through selection. Table 1 provides a detailed composition of these varieties per the companies that developed them.

ENRICH POULTRY MEAT AND EGGS WITH OLEIC ACID

Due to the properties of oleic acid products indicated above, it has been suggested that meat products and eggs could be enriched with this fatty acid by feeding chickens, hens, and fish whole soybean meal and other oilseeds.

In collaboration with the USDA-ARS, our research group at North Carolina State University developed a research project to evaluate the use of higholeic extruded whole soybeans.

- A non-genetically modified variety similar to SOYLEIC® but from the USDA selection process in Raleigh, North Carolina, was used. The nutritional composition, energy value, and amino acid digestibility of extruded whole soybeans from high oleic soybeans were evaluated in several experiments.

The inclusion of extruded whole soybeans was evaluated in hen and chicken diets to observe the impact on bird performance, growth, egg production, and feed conversion.

Likewise, the impact on meat and eggs was evaluated, especially on the lipid profile of these products.

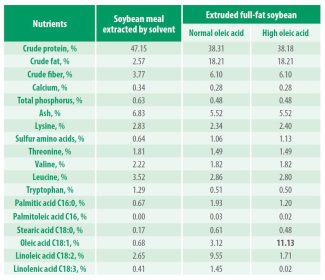

- In these experiments, the results of high-oleic soybean meal were compared with diets that included traditional soybean products with average oleic content, such as soybean meal extracted by solvent and extruded full-fat soybeans.

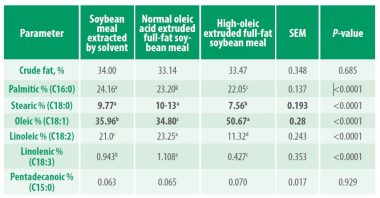

- The nutritional composition of the evaluated products is presented in Table 2.

The research results indicated that extruded high-oleic full-fat soybeans have an energy content similar to traditional or normal-oleic full-fat soybeans (3,112 kcal/kg AMEn) and higher than solvent-extracted soybean meal. The digestibility of the two extruded full-fat soybeans is almost the same for all amino acids (80 to 87%) and consistently 3 to 10% points lower than that of solvent-extracted soybeans.

EFFECT OF HIGH-OLEIC EXTRUDED SOYBEAN MEAL ON HEN PERFORMANCE AND EGG FATTY ACID PROFILE

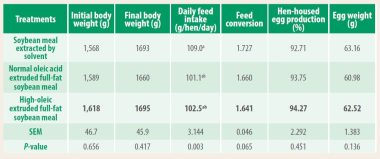

Including high-oleic extruded full-fat soybeans did not significantly affect weight, feed intake, feed conversion, egg production, or average egg weight (Table 3) compared to hens fed containing the other soybean sources evaluated.

- The only parameter affected by the treatments on egg quality was yolk color (Table 4).

- Extruded whole soybeans ended up with paler yolk colors.

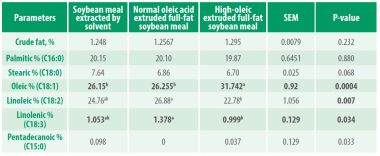

However, the fatty acid profile of the soybeans was affected, increasing, as expected, the oleic acid and reducing the palmitic, linoleic, and linolenic acid when the extruded full-fat soybeans with high oleic content were included (Table 5).

The total fat content of the yolk was not affected by the treatments.

EFFECT OF HIGH OLEIC SOYBEAN MEAL ON CHICKEN AND MEAT PERFORMANCE

Broiler chicken body weight gain and chicken feed conversion were lower for diets with normal oleic or high oleic extruded whole soybeans.

- The higher levels of trypsin inhibitors from full-fat extruded soybeans probably affected performance.

- Improving the process can overcome this issue.

- Carcass yield was also reduced with high oleic extruded soybeans.

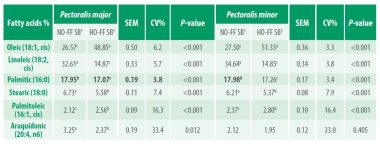

- However, the soybean meal source affected the fatty acid profile of chicken meat (Table 6).

- Diets with high oleic extruded whole soybeans increased oleic acid and reduced linoleic and linolenic acid.

- A similar effect was observed in the meat of laying hens fed with these same soybean meal sources (Table 7).

- A reduction in palmitic, palmitoleic, and arachidonic fatty acids and other saturated fatty acids was observed in poultry meat.

CONCLUSIONS

- Extruded full-fat soybeans with high oleic content can be included in feed for chickens and layers.

- In extruded soybeans, paying greater attention to the levels of trypsin inhibitors to avoid adverse effects on performance, especially for broiler chickens, is essential.

- The energy value and amino acid digestibility of this soybean with higher oleic acid content is similar to that of traditional extruded full-fat soybeans.

- The high oleic acid content is effectively transferred to eggs and meat, reducing linoleic and linolenic acids.

- These poultry products are expected to have greater oxidation stability during storage.