Available in other languages:

Content available at:

Español (Spanish)

For many years, the commercial incubation industry has relied almost entirely on the multi-stage (many loads) incubation methods, and with good results. The concept of thermal interaction efficiency between endothermic and exothermic eggs, as well as its ease of use, has made this the ideal solution.

However, as chicken consumption grew worldwide and the poultry industry became intensive, it became clear that the multi-stage method could not meet the level of biosecurity required by the modern market.

Furthermore, the academic world clearly demonstrated that multiple-stage incubation was unable to provide optimal conditions for the developing embryo.

For a time, many publications and articles theorized about the potential of a single-stage (1 loading) incubation as a solution to both biosecurity issues and providing optimal conditions required by the embryo.

However, the first single-stage methodologies posed difficulties in obtaining the same results as their multi-stage counterparts.

The challenge of single-stage, for both commercial incubator manufacturers and academics, was to identify the ideal conditions for the embryo and create an incubator that could generate such conditions on a large scale.

It was almost inevitable that during this period there would be a debate between supporters of multi-stage and single-stage, but today it cannot be doubted that a modern well-managed single-stage hatchery can produce results – both pre and post-hatch — superior to the best possible results in a multi-stage hatchery.

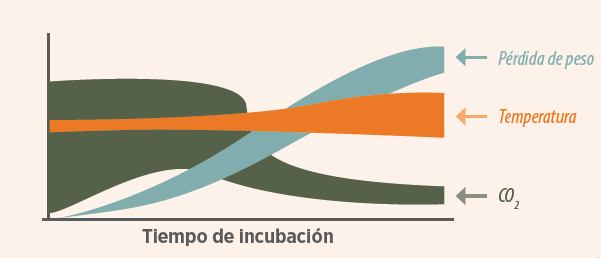

The following chart shows the optimal ranges for the developing embryo through key parameters such as temperature, humidity, and CO 2.

TEMPERATURE

As the main parameter, it is more accurately described as the absorption and dissipation of energy produced through heat exchange. Many academic studies and commercial trials have shown how precise temperature control – which cannot be achieved in a multi-stage environment – positively and significantly affects both chick quality and all aspects of post-hatch performance.

Graph 1. Variable requirements of the hatching egg depending on the incubation period

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón