Increasing global demand for eggs combined with animal welfare concerns underscores the need to improve laying cycles, with many producers continuing to 100 weeks.

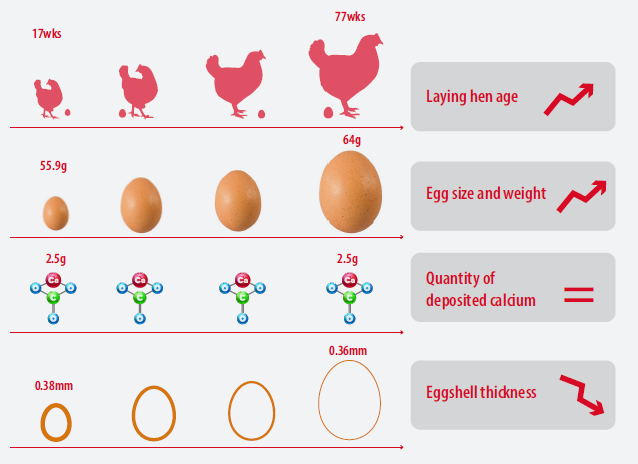

As laying hens age, they produce bigger eggs. However, the amount of calcium deposited remains constant, resulting in thinner and more fragile shells, leading to a higher percentage of downgraded eggs and therefore economic loss (Figure 1).

Figure 1 : Evolution of egg characteristics during cycle production, based on data coming from a meta-analysis encompassing over 3433 brown eggs (under submission, Lallemand internal data).

ASSESSING EGGSHELL QUALITY

Lallemand developed a device to assess eggshell quality through the measurement of specific gravity (SG) (Figure 2).

Egg SG is mainly driven by eggshell SG, which is highly correlated with eggshell thickness and eggshell strength. It is acknowledged that a SG above the 1.08 reference value reflects good eggshell quality, while a value below this threshold indicates poor eggshell quality. This method enables the comparison of different groups of eggs by classifying them into two distinct categories based on eggshell quality.

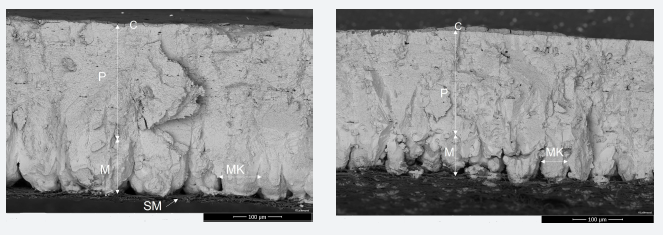

The scanning electron microscope images below (Figure 3) illustrate the ability of SG to reflect eggshell quality.

Figure 3: Scanning electron miscroscopy of the eggshell cross section (from laying hen eggs). Cuticule (C), Palisade Layer (P), Mammillary Layer (M) and Mammillary Knobs (MK) and Shell Membrane (SM).

SG measurement, a non-invasive method, can be used to validate beneficial effects of Pediococcus acidilactici CNCM I-4622 (BACTOCELL) on eggshell quality during the production cycle.

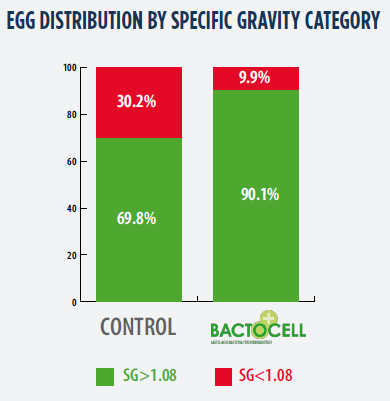

Figure 4: Comparison of egg specific gravity distribution from layers supplemented with BACTOCELL versus control hens. Data from a meta-analysis under submission.

A meta-analysis comparing control eggs with eggs from BACTOCELL-supplemented hens was conducted in early 2025, based on 1104 brown eggs.

A supplementation of 100 g (1000 billion CFU) of BACTOCELL per ton of feed shows beneficial effects on the eggshell SG (Figure 4). The percentage of eggs with a low SG, and therefore a poor eggshell quality, is only 9.9 % for BACTOCELL eggs, but is over 30% for control eggs.

This better eggshell quality has also been demonstrated by measuring eggshell thickness which was significantly improved by 15% with the use of BACTOCELL (P <0.001). This improvement in eggshell quality resulted in a significantly lower percentage of downgraded eggs : 3.5 % for control eggs vs 0.0 % for eggs laid by BACTOCELL-supplemented hens (P <0.001).

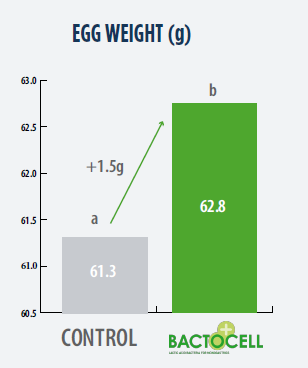

Figure 5: Comparison of egg weight from layers supplemented with BACTOCELL versus control hens. Data from a meta analysis under submission (P<0.001).

This meta-analysis demonstrates that the use of this probiotic increases exported egg mass, while improving eggshell quality.

BACTOCELL is a lactic bacteria Pediococcus acidilactici CNCM I-4622 (MA 18/5M), validated and registered in the EU as zootechnical additive for all avian species (feed, drinking water).

These beneficial effects have been repeatedly demonstrated in different trials, and it appears that BACTOCELL, by supporting gut health, enhances bird utilization of dietary mineral sources. Recent research1 investigating this mechanism showed that the use of BACTOCELL promotes an increase in two key hormones of calcium metabolism (calcitriol and osteocalcin), resulting in higher circulating levels of calcium and phosphorus. Therefore, BACTOCELL enhances calcium assimilation and mineralization, supporting laying hens throughout their production cycle and improving eggshell quality.

REFERENCE

1 Shanmugam, S., Barbé, F., Park, J.H. et al. Supplemental effect of Pediococcus acidilactici CNCM I-4622 probiotic on the laying characteristics and calcium and phosphorus metabolism in laying hens. Sci Rep 14, 12489 (2024). https://doi.org/10.1038/s41598-024-62779-5

“More references available upon request. Not all products are available in all markets nor associated claims allowed in all regions.”

Subscribe now to the poultry technical magazine

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón