Available in other languages:

Content available at:

Español (Spanish)

By Marleen Boerjan

R&D Director, Pas Reform Academy

If temperature ( 18-20 ° C; 64.5-70 ° F) and relative humidity (75%) in storage rooms are properly controlled, eggs can be stored for a week without having their hatchability or post-hatch chick quality characteristics affected. However, longer storage periods negatively impacts the vitality of the embryo, which causes ( Fasenko, 2007; Dymond, 2013 ):

To overcome this limitation, hatchery managers are testing new approaches of egg storage management.

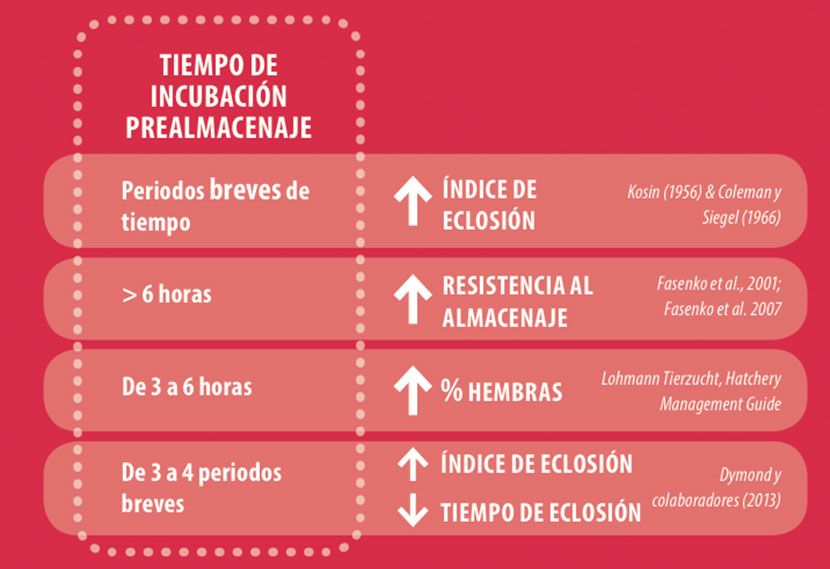

In the 1950s and -60s, Kosin (1956) & Coleman and Siegel (1966) showed how hatching rates increased when eggs were incubated for short periods of time before being stored.

At the beginning of the century, Fasenko (Fasenko et al., 2001; Fasenko et al. 2007) showed how after six hours of pre- storage incubation, chicken embryos reached the stage of embryonic development of the hypoblast, rendering them more resistant to storage.

Subsequent introduction of 3-6 hours of pre- storage incubation in layer hatcheries has shown that eggs stored for more than 11 days produce 3-7% more females (Lohmann Tierzucht, Hatchery Management Guide).

In the broiler industry, this pre-incubation embryo thermal stimulus from pre-incubation has been further adapted to allow multiple stimulus periods.

Dymond et al. (2013) have shown how three to four ‘Short Periods of Incubation During Egg Storage’ (‘SPIDES’) of 21 days increased hatching rates and reduced hatching times, compared to 21-day old eggs without incubation (control group).

The SPIDES method has been presented by the genetic company Aviagen in its manual no.9, and suggests: “Improve hatching rates by using Short Periods of Incubation During Egg Storage (SPIDES)”.

Implementing SPIDES:

The time required to reach 32 ° C (90 ° F) varies depending on the type of incubator, but it is typically after 3 to 6 hours of incubation at 37.8-38 ° C (100.0-100.4 ° F).

To prevent embryos from developing beyond the storage resistant stage, attention must be paid to the fact that during the entire treatment, or multiple SPIDES treatments, the accumulated time in which the temperature of the eggshell is above 32 ° C (90 ° F) does not exceed 12 hours. (See HOW TO in Aviagen’s manual No. 9 for more details)

If temperature and relative humidity are controlled in storage rooms, neither the hatch rate nor the chick quality will be significantly affected.

It has been shown that one pre-storage treatment, or multiple SPIDES treatments, improves hatching rates and chick quality if the eggs are stored for seven days or more.

The interval between each SPIDES is typically 5 to 6 days. Pre-storage incubation and SPIDES treatments change hatchery management significantly.

However, this can be financially compensated by the recovery of incubation rates. SPIDES management protocols need to be specifically designed according to the management forms and equipment of each specific hatchery.

-Make a cost-benefit analysis to determine if SPIDES management is economically advantageous.

– Avoid increasing the size of the hatching window by preheating and uniformly cooling the eggs in the incubator.

-Conduct small-scale tests to establish the appropriate schedule and duration of incubation treatments during storage, according to the specific characteristics of the eggs and the incubation room.

-Start the SPIDES treatment only when all the eggs have been preheated to 25 ° C.

-Perform the SPIDES treatment only when the eggs are in the incubator trays to ensure a uniform temperature distribution for the eggs during incubation.

-SPIDES treatment on cardboard trays is not possible.

-Cool the eggs in the incubator as soon as the temperature of the eggshell reaches 32 ° C (90 ° F) and always before returning them back to the storage room.

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón