13 Jul 2020

Quality control and monitoring guide for hatcheries

Content available at: Español (Spanish)Quality control programs for the hatcheries and breeder farms should be designed so that data can […]

Available in other languages:

Content available at:

Español (Spanish)

Quality control programs for the hatcheries and breeder farms should be designed so that data can be generated to document the outcome of all major procedures implemented on both these sites.

The quality of the chicks produced at the hatchery depends on various factors present on the farms, during egg transport, or in the environment and management of the hatchery. This short guide is to encourage hatchery managers to follow up on some of the most important incubation management areas.

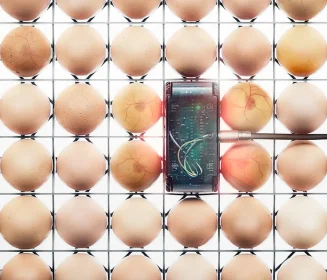

The first requirement in egg health is to determine that the temperature of the hatching eggs is always going down continuously from the farm’s storage room to the hatchery’s storage.

The temperature of the eggs must not fluctuate, as this can lead to condensation on the shell’s surface and produce what’s known as “egg sweating”. The temperature should always scale down as from the farm, followed by the transport truck and eventually the hatchery’s storage room.

HIGH HUMIDITY AREAS

If the hatchery is located in an area with high relative humidity and where there are no appropriate control systems, it will be necessary to store the egg at not very low temperatures. In this way, there is no condensation of water in the transition between the cold room and pre-incubation or incubation, as this problem is one of the main causes of contamination in hatcheries and newborn chicks.

Although the purpose of this article is not to specifically address egg handling at the farms, it is important to mention that:

- Egg collection systems

- Collection frequency

- Egg disinfection

- Egg storage and transport temperatures to the hatchery

Are all aspects for which there must be defined procedures and a series of data documentation for improved monitoring.

Subsequently, data such as the percentage of eggs that don’t meet these standards will have to be documented.

For example, it may be established not to use floor eggs after 30 weeks of age. Or for example, any egg that has fecal or blood stains over half a centimeter in diameter can be rejected. The important thing is to set the parameters and stick to them.

There are many egg disinfection systems, some of them based on fumigation, others on wet disinfection, thermal fogging, and others based on gases. However, many companies today do not disinfect hatching eggs due to environmental protection or public health restrictions for employees.

There is a lot of research documenting:

- Average temperatures

- Humidity

- Temperature fluctuations

- Short pre-incubation periods during egg storage (SPIDES)

All these play important roles for hatching efficiency and chick quality.

In many countries there are still hatcheries where there is no possibility to control the relative humidity of the incubators or any other area within the facilities.

In these circumstances, the storage of eggs at temperatures not too low should be considered, in order to avoid condensation on the shells as they are moved from the cold chamber.

TO CONTINUE READING REGISTER IT IS COMPLETELY FREE

Access to articles in PDF

Keep up to date with our newsletters

Receive the magazine for free in digital version

REGISTRATION

ACCESS

YOUR ACCOUNT

LOGIN

Lost your password?