Content available at: Indonesia (Indonesian) Melayu (Malay) ไทย (Thai) Philipino

The Reasons Why the World is Moving to Community Nests

Our world of broiler breeders at grandparent and parent stock levels is moving fast to more technification, trying to reduce the cost of hatching eggs and to manage larger breeder flocks with less labor available and receive a higher quality egg.

- Many countries suffer from labor shortages, and the available hand-labor is often of reduced technical quality and needs a lot of training and constant education.

- Egg collection is a daily activity that may take more time.

- There are currently two production house configurations related to higher technification or automation for broiler breeders worldwide. In this article, we will call these two systems the US and the European concept.

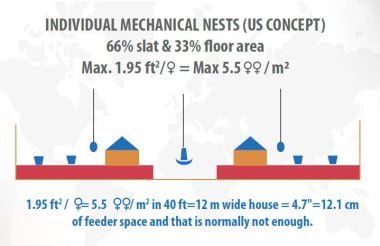

THE US CONCEPT:

Here, we have basically all the nest, feeding, and drinker equipment for females on the slats. The house has a central scratch area for the males with their feeding system. Males need to go on the slats to drink.

This US concept has a significant advantage: the floor eggs are often low. Still, a significant disadvantage is that female density cannot go lower than 1.95 ft2/female or higher than 5.5 females/m2, and that is, in theory, already on the high side, then feeder space is shorted to only 4.7” (12.1 cm).

- Adult hens need 6” (15 cm) for all birds to eat at the same time. This is especially important in the period from 21 weeks to peak production, when feeding cleanup times can be very fast if crumbled or pelleted feed is used.

The other disadvantage is that slats need to be at least 17.7” (45 cm) in height to avoid over time that the droppings will accumulate below the slats and come up through the slats, dirtying and contaminating the feet of the hens.

- A high slat often requires more use of litter to reduce the step-up distance, which is more costly, and more litter will entice hens to lay in the scratch area, causing a loss of hatching eggs or more contamination.

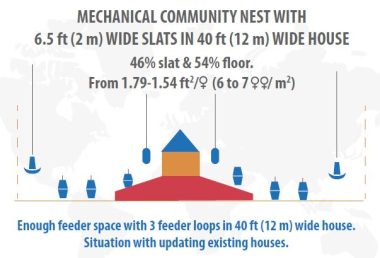

THE EUROPEAN CONCEPT:

This concept uses large community nests in the middle of the house, giving more space to the total house area to add more feeder space and, with that, the possibility of increasing female density considerably. This is a great advantage for the grower, increasing his return on investment (ROI) considerably and getting easier bank loans with higher income. The US market could benefit greatly from this concept.

- Higher female density is the single most important factor in reducing the fixed house investment per hen, reducing the cost price of hatching eggs. The concept has been proven over the last 30 years in many parts of the world. It is important to realize that we do not include males in the density calculations.

-

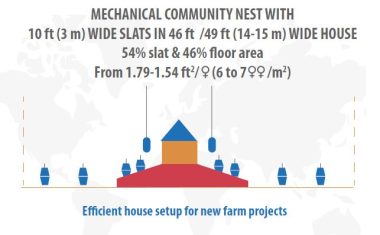

To construct the new house, the idea is to build 46 ft or 49 ft (14-15 m) wide houses to maximize the utilization of feeder, drinker, and nesting space. Another feeder loop will be added, bringing the total to four feeder loops, which will give more than enough feeder space for the hens.

With the community nest concept, hard wooden slats are used that give the possibility to have a low slat height of 14” (35 cm) in the first part of the production period and then raise the height of the slats very easily to 18” (45 cm) in the 2d part of the production when the droppings are nearing the slats.

- Hens have the terrible habit of producing droppings when they jump on the slats.

- This gives more accumulation at the slat step-up area.

- The slat height cannot be adjusted with plastic slats, and the negative points of plastic slats will be discussed in the following articles.

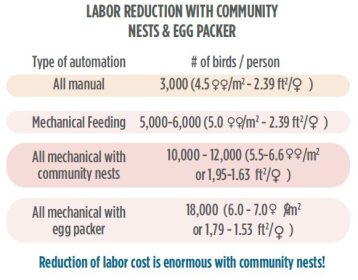

The following table clearly compares the most simple mechanization concept with community nests. As a next step in automation, using an egg packer can increase the number of hens per person and thus considerably reduce labor costs, besides reducing the fixed costs per hen due to higher bird densities.

Increasing female density is the main reason the world is adopting the European community house concept and not the US house configuration.

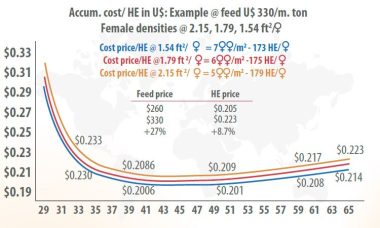

- Increasing bird density will generally reduce the hatching egg (HE) production per hen, but it is easily compensated by the higher HE output per ft2 or per m2, reducing the overall cost / HE.

- Increasing the female density does not generally affect fertility or hatchability as long as sexually synchronized active body weight-controlled males are used.

CONCLUSION

The world is moving fast towards community nests due to the possibility of increasing bird density to reduce the investment cost per hen and the cost price of the hatching eggs.