Animal Nutrition

Why should we segregate soybean precision nutrition meals by origin in poultry feed formulation?

To read more content about aviNews International December 2023

Animal Nutrition

To read more content about aviNews International December 2023

Content available at:

Indonesia (Indonesian) Melayu (Malay) ไทย (Thai) Tiếng Việt (Vietnamese) Philipino

POULTRY.

PRECISION NUTRITION

In times of high market volatility, precision nutrition gets special attention. One of the main aspects of precision nutrition is to improve the information needed for decisionmaking, planning, and optimization.

Feedstuff and feed costs drive a significant portion of production costs in poultry.

Variability in feedstuff nutrient content is a crucial factor to control when attempting to reduce feed costs, improve feed quality, and optimize animal performance and company profitability results.

A logical and relatively easy way to reduce variability is to segregate ingredients by origin, provider, or quality.

These difficulties in feed manufacturing limit the number of groups we can have for every feedstuff.

However, recognizing the differences in nutrient composition, energy value, and quality will make the feed formulation more precise and minimize feed costs if the feedstuff selected has a good nutrient quality and energy value.

Segregating by origin mitigates risks of producing feed that does not meet the expected specifications.

Treating key feedstuffs as average ingredients or commodities instead of differentiated products could cause overestimation or underestimation of their nutrient and energy values.

Amy Moss et al. (2021) calculated that overestimating the nutrient content of feedstuffs could result in broiler performance reduction and a 63% reduction in gross margin.

This equates to a loss of up to $6.3 million US dollars for every 10 million broilers. Consequently, proper sampling methods of all feed ingredients are needed to estimate their nutrient and energy value.

SOYBEAN MEAL VALUE

The most expensive components in chicken diets are energy and protein or amino acids. Soybean meal (SBM) is the most important source of amino acids in poultry diets worldwide.

The SBM also provides between 20 and 30% of the metabolizable energy (ME) in most poultry diets.

Consequently, accurate estimation of the amino acid and caloric value of this ingredient is critical for precise feed formulation.

The SBM market prices are frequently determined based on trading rules specifying minimum crude protein (CP) content.

However, it is essential to consider that the dietary value depends on many other nutritional and processing quality factors in poultry, and it is almost impossible to segregate SBM only by CP content in a feed mill.

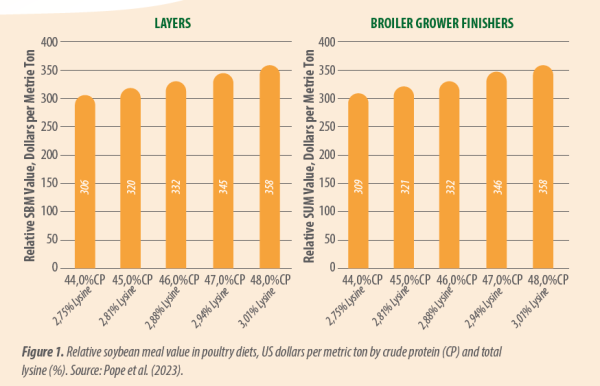

A recent economic evaluation by Pope et al. (2023) quantified the value of SBM in poultry and swine diets affected by their nutrient content. Their data was obtained using five SBM CP contents (44, 45, 46, 47, and 48%).

They calculated ME, amino acid content, and digestibility values with linear regressions or standardized equations for those five levels of CP concentration.

This group concluded that increasing SBM CP content by 1% increases the relative SBM value by $12.62 per metric ton (MT) in poultry diets.

The relative SBM economic value ($/MT) was estimated in this study based on the changes in the nutritional properties of the SBM (amino acids and energy).

Relative value of SBM ($/MT) = Base SBM price ($/MT) – [TDC test – TDC Base)/ SBM test x 1000]

Where “TDC” is the total diet cost ($/MT), assuming the inclusion of the specified SBM, and “SBM” is the amount of SBM included in the diet (kg/MT).

The group led by Micah Pope used those SBM in broiler grower and finisher diets and in one layer diet to obtain these values. The relative value of the SBM also increased as the CP increased (Figure 1).

The data showed that the 48.0% CP SBM (3.01% total lysine) has a premium of US$ 49 in broiler diets and US$ 52 in layer diets per MT over 44.0% CP (2.75% total lysine). It was also noted that the relative value of SBM was similar across both poultry groups.

SOYBEAN MEALS VARY BY COUNTRY OF ORIGIN

The SBM are traded globally, and the major SBM producers are the USA, Brazil, Argentina, and India. SBM can vary due to numerous factors, including seed variety, agronomic and harvesting conditions, soybean processing, and storage.

Several studies have been conducted in the past 20 years to determine which factors are more relevant in SBM variability.

There is clear evidence that SBM varies by country of soybean origin. This could be related to the latitude, solar radiation, and prevalent weather during plant growth.

Consequently, this could be the main factor for SBM segregation in feed mills that receive feedstuffs from diverse countries of origin or a factor for decision-making in selecting providers during purchasing.

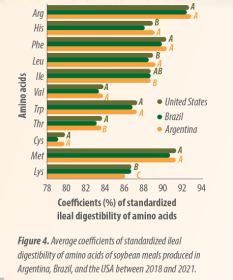

The information from 18 published studies with a total of 1944 SBM samples was summarized in a meta-analysis by Ibáñez et al. (2020). This data indicates that:

The origin of the beans has consistent and significant effects on most of the chemical variables of the corresponding SBM. The Brazilian SBM had more CP, neutral detergent fiber, raffinose, and iron but less sucrose, stachyose, and potassium than the USA or the Argentinian SBM.

The USA meals had more sucrose and stachyose but less raffinose. Per unit of protein, Lys, Met, Thr, and Cys concentration were greater for the USA and Argentinian meals than for the Brazilian and Indian meals.

NIRS TO ESTIMATE NUTRIENT CONTENT AND ENERGY VALUE

All those scientific studies have been conducted with selected SBM samples and analyses conducted in multiple laboratories.

Consequently, there is variability among labs and sampling times for each analysis. One tool that can minimize this inter and intra-laboratory variability is the near-infrared spectroscopy (NIRS).

Calibration curves have been developed to estimate with NIRS spectra the proximate analysis, amino acid content, and other nutrients.

Most of these developments have been conducted by commercial companies. Adisseo developed the Precise Nutritional Evaluation (PNE) service based on NIRS technology.

The calibration curves to determine apparent AME and AME corrected by nitrogen (AMEn) and the digestibility coefficients of all essential amino acids are based on in vivo data, and are obtained with a direct calibration.

In this case, the same sample used to produce NIRS spectra can generate multiple parameters influencing nutritional quality. This PNE system has been used worldwide for several years; consequently, a large dataset was available.

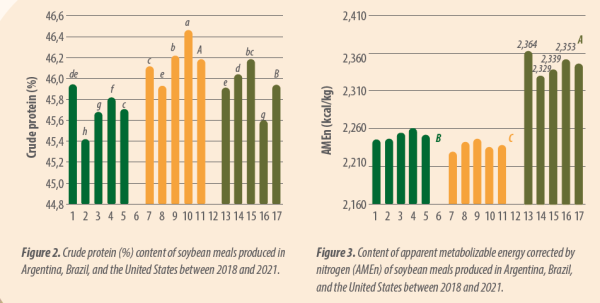

In a collaboration study with Adisseo, we explored their NIRS database of 77,621 SBM samples evaluated between 2018 and 2021 from Argentina, Brazil, and the USA.

Results indicated that SBM varied by country of origin, and there was variability due to harvest year. In general, and across years, Brazilian SBM had the highest CP (Figure 2), fat, and CF values but the lowest AME and AMEn (Figure 3).

These variations in nutrient and energy values seem to be minor. But, when they are included in the feed ingredient matrix in a least-cost formulation software, creating one SBM for each country of origin, our results indicate significant differences in feed costs.

We used the average proximate data, amino acid and energy content, and digestibility coefficients observed by PNE in the SBM produced in Argentina, Brazil, and the USA in 2020 and 2021.

THE VALUE OF SEGREGATING SOYBEAN MEALS BY ORIGIN

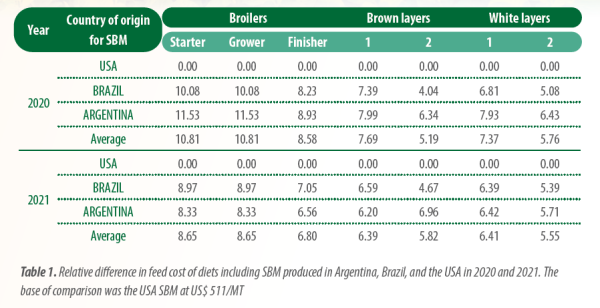

The feed costs indicated that formulating with USA SBM could make broiler and layer diets cheaper than diets including Argentinian and Brazil SBM. The differences in feed costs relative to the feed with the inclusion of USA SBM are presented in Table 1.

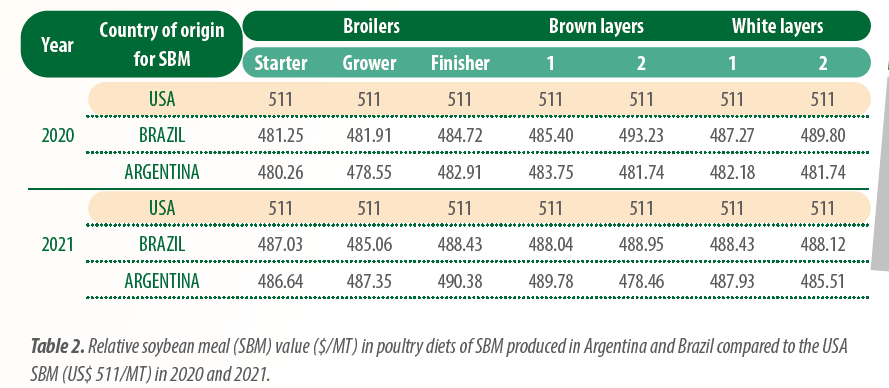

Using the same formula used by Pope et al. (2023), we estimated the relative SBM values (Table 2) of Argentinian and Brazilian SBM compared to USA SBM in two years. The results indicate lower relative SBM values for Argentinian and Brazilian SBM.

The USA SBM will have a premium of US$ 17.77 to US$ 32.45 per MT over the SBM produced in Argentina and Brazil when used in broiler and layer diets.

Broiler starter, grower, and finisher diets and four table-egg layer diets were formulated to meet genetic line recommendations in poultry.

This information confirms that SBM should be segregated by origin, and those minor variations in nutrient and energy contents can considerably affect feed costs.

This is vital during periods of volatile markets. Additionally, segregation can enhance the probability of meeting diet specifications and obtaining the desired poultry performance results.