1.- Uniform preheating

Content available at:

Español (Spanish)

Every day the customer demands more quality in the chicks that the hatchery delivers to his farm. Quality is measured in low mortality and good weight gain in the first days. Below we will describe 5 operations that will contribute to improving the quality of your chicks.

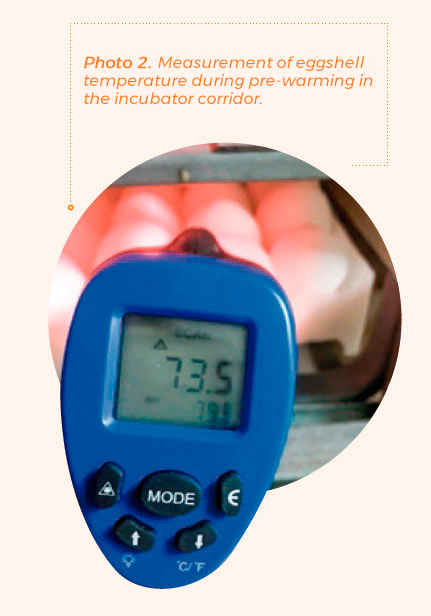

1.- Uniform preheating

This management seeks that the eggs that are in the cold room at 15-16 ° C achieve a temperature above the physiological zero (20-25 ° C) in the most homogeneous way possible before the incubation profile starts. The time to reach 25 ° C varies depending on the age of the breeders and the breed. Inside the single-stage incubator it is around 5 to 6 hours and in the corridor 12 hours. Check it!! Every hatchery is different !!

What is the purpose of preheating?

To synchronise the hatch time of all the eggs placed inside the incubators and not have hatched chicks waiting for the slower ones inside the hatchers, causing them to get dehydrated and decreasing the uniformity of the flock upon arrival at the farm. In multistage machines, this handling helps the loaded eggs to not drastically reduce the temperature of the ones already inside and reduces the possibility of eggs sweating, however it has the negative consequence of bacterial contamination –Photo 1–

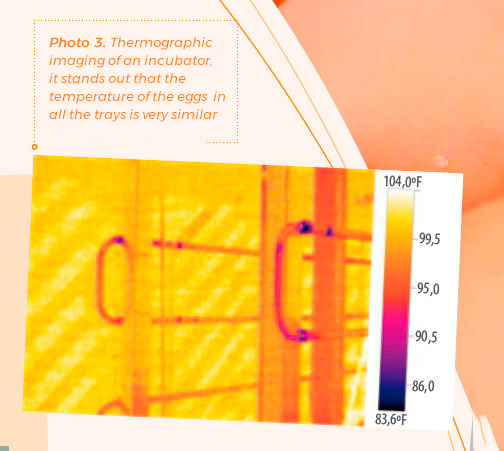

Single-stage incubators

Single-stage incubators are ideal for preheating since due to their ventilation, the heat is distributed evenly within the machine and prevents eggs from sweating. In the case of multi-stage, it can be done in a nearby room, making sure that all the egg trolleys are exposed to the same temperature or in the corridor in front of the machines. It should be noted that some researchers recommend that eggs from older birds be preheated to lower temperatures for a longer period of time.

Meijerhof et al –1994– reported that 58-week-old breeder eggs pre-heated 16 hours at 20 ° C had a larger hatching than pre-heated 16 hours at 27 ° C (89% Vs 85.1%).

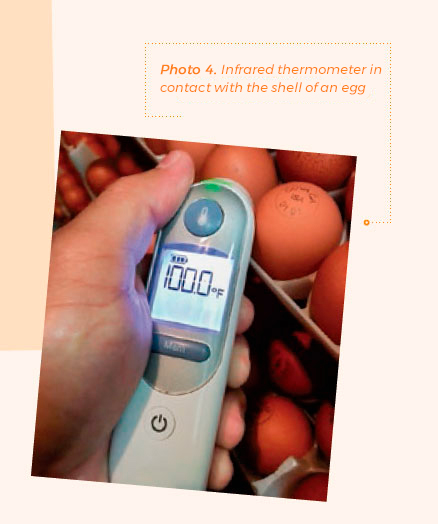

2.- Correct embryonic temperature

Temperature is a crucial factor for the quality of our chicks. Most genetic companies and hatchery manufacturers recommend embryonic temperatures close to 100 ° F (37.78 ° C).

It should be noted that studies carried out at much lower temperatures (36.7 ºC = 98.06 ° F) in recent days have reported better yolk-free muscle mass and a higher proportion of heart weight with respect to the body –Maatjens et al 2014–. Embryonic temperatures above 100 ° F (37.78 ºC) generate up to 5% more second-grade or to-be-culled birds–Lourens et al 2005–, due to problems with legs and unhealed navels (black buttons); and with less body mass free of yolk sac. They are birds with good weight but with a percentage of unused yolk sac that is often greater than 20% of the total weight of the chick (ideal is less than 10%). In other words, due to the high temperature, the embryo that was growing stopped using the nutrients of the yolk and used muscular glycogen –Maatjes et al 2014; Leksrisompong et al 2007–.

Additionally, the high temperature reduces the incubation time and therefore the opportunity to use available nutrients in the yolk, especially proteins –Molenaar et al 2010–. Photo 5 shows a very large yolk sac from a bird exposed to high temperatures, particularly in the last week of incubation.

In Photo 6 ,a chick just taken from a hatcher (moisture in neck feathers) with a small yolk sac as a result of good body mass.

Lourens et al 2005 and Joseph et al 2006 reported that chickens incubated at high temperatures (38.9-39.5 ° C) between 7 and 21 days, reached up to 13% less weight per week of age.

3.-Adequate humidity

During the incubation process the eggs must lose weight (water) so that an adequate air chamber is formed to facilitate the hatching of the birds. The maximum hatch is reached when the weight loss is between 12 and 14% at the transfer –Ar and Rahn 1980–.

Hatch is brought forward perhaps because the air would have less capacity to move heat and thus the temperature of the embryo would be higher. When hatching before the scheduled time, the birds would lose weight during their wait.

If the humidity is high, the formation of the air chamber will not be adequate, making it difficult for the birds to free themselves from the shell –Photo 7–, many will get tired and get trapped, and others after exertion will come out but many times injuring their elbows –red elbows -.

If the humidity in the hatchers is very high after the birds hatch, the percentage of birds discarded due to umbilical “threads” will increase –Photo 8–

4.-Correct temperature

After the chicks are sexed and vaccinated, they are housed in a waiting room to be loaded onto trucks for shipment to the farms. The waiting room should provide the ideal ambient conditions for the birds to find their comfort zone without making unnecessary metabolic costs. You should remember that chicks, the first 4-5 days after hatching, do not fully regulate their temperature and depend on the ambient temperature that surrounds them.

5.-Management

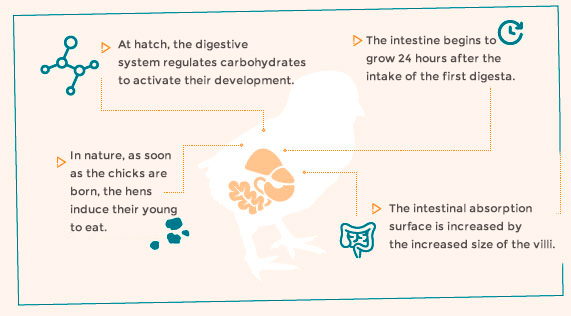

At the time of hatching, the chicks have some not fully developed physiological systems, including the digestive, immune and thermoregulatory systems.

During the incubation process the nutrients of the chick in formation come from the yolk – being mostly lipids- and the albumen. .

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón