Content available at:

Español (Spanish) Português (Portuguese (Brazil))

One third of the total life cycle of a chicken until it reaches the slaughterhouse occurs in the hatchery: 20-21 days of incubation + 35-40 days on the farm. Hatchery management and practices can help express the full genetic potential of the chicks. Compromising it will lead to the worst case scenario, which is mortality upon reaching the farm.

Based on the fact that our eggs come from disease-free birds, we must verify that:

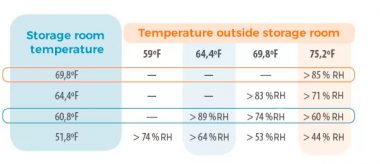

We must have control over the temperature of the eggs when they are taken off the truck and moved inside the hatchery. An increase in temperature can cause eggs to “sweat”. By lowering the temperature again after entering the hatchery, pathogens that were on the surface of the shell can gain access to the inside of the eggs. Said pathogens can eventually cause either embryonic death during incubation or be present in the birds post-hatch and cause on-farm mortality.

Preheating

The objective of preheating is to ensure that the eggs, before being placed in the incubator, have a similar temperature and degree of development, helping to ensure that the largest number of birds hatch at the same time and that they do not dehydrate unnecessarily in the hatchers while waiting for the other birds to be ready.

Preheating time should be as long as it takes for the internal temperature of the eggs to reach 25°C (77°F)

Temperature

The embryonic temperature is the most determining factor not only for birth but also for adequate body development and, therefore, good survival on the farm.

Very high levels of carbon dioxide (over 1000 ppm in the hatchery; over 3000 ppm inside the incubator) are the result of inadequate ventilation and should be checked. In hatchers, the highest level inside the machine should not exceed 6000 ppm; it is usually around 3500-4500 ppm. After the birds are hatched the CO2 level should be below 2500 ppm. Without a correct oxygen level in the hatchers, the mechanism of yolk bag utilisation is compromised.

Humidity

The humidity of the incubators must be such that during transfer time, the eggs have lost around 12% of their initial weight. Very low weight losses will be reflected in smaller air cells, which will cause difficulties for the birds to get out and therefore cause injuries known as red elbows (hocks).

Hatch Window

Measuring the hatch window must be a routine practice. It provides us with vital information on the number of total incubation hours that the eggs require, since due to different management at the farm, the conductance of the shells can change and, therefore, the incubation profile that has been used successfully can now be incorrect.

In broilers, a maximum of 2% of the birds must be hatched 30 hours ahead of the scheduled time for them to be processed.

After the vast majority of birds have hatched, their body temperature should be measured and adjusted to be between 103-104°F (39.4-40°C). During the process of sexing and vaccination, the birds’ body temperature may drop, but they should recover it in the waiting room before being transported. Higher or lower temperatures result in greater weight loss. After processing, the birds should be sent to the farm as soon as possible to eat and drink

An unnecessary waiting for birds to start feeding and drinking will only contribute in delaying intestinal development, the use of antibodies, and weight loss.

The survival of the birds on arrival at the farm depends largely on how the environmental conditions were during incubation.

Embryonic temperature, weight loss, hatch window or cloacal temperature are some of the necessary measurements to be carried out to guarantee optimal embryonic development and the well-being of the birds.

Subscribe now to the poultry technical magazine

AUTHORS

Layer Longevity Starts at Rearing

H&N Technical Team

The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto

Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control

Edgar O. Oviedo-Rondón

GREG TYLER INTERVIEW

Greg Tyler

Insights from the Inaugural US-RSPE Framework Report

Elena Myhre

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo

Avian Pathogenic E. coli (APEC): Serotypes and Virulence

Cecilia Rosario Cortés

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón