MINIMIZING DAMP LITTER PROBLEMS IN THE HOT SEASON

Contenido disponible en: Español (Spanish)Mike Czarick and Brian Fairchild, Department of Poultry Science, University of Georgia, Athens, Georgia 30602 The […]

Mike Czarick and Brian Fairchild, Department of Poultry Science, University of Georgia, Athens, Georgia 30602

The correct management of litter moisture during cold seasons has always been a great challenge in thermally poorly isolated sheds, with a low air exchange rate, and when fuel prices are high.

However, at present many farmers are realizing that maintaining good litter conditions during the hot season can also be problematic, even in the best possible facilities.

One major reason for making it difficult to control litter moisture during high temperature times is the tendency to breed increasingly heavier or increasingly older chickens.

Heavier or older chickens require lower ambient temperatures in order to keep them comfortable.

A suitable temperature can be approximately 75°F (23.9°C) for those who breed four pound chickens (1.8 kg).

For farmers breeding seven- or eight- pound chickens (3.17 to 3.6 kg), though, the temperature during the last week of the flock’s life must be at least 10°F lower (65°F / 18°C) than the required temperature for smaller or younger fowls.

Temperature setting recommendations for the last week of the flock’s life, depending on the final weight of the chicken

When breeding very heavy chickens, we may need to use evaporative or cooling panels daily for at least 30 days, thus increasing the risk of damp litter problems.

This need to keep lower temperatures will inevitably bring about an increase of the need to use evaporative or cooling panels to be able to maintain the required temperature in the shed during warm seasons.

Evaporative or cooling panels are normally used for only one or two weeks in the flock-rearing period, though farmers who breed very heavy chickens might need to use them every day, even for up to 30 days, thus increasing the likelihood of damp litter problems.

It is as simple as that: the more an evaporative or cooling panel is used, the more likely are damp litter problems to occur.

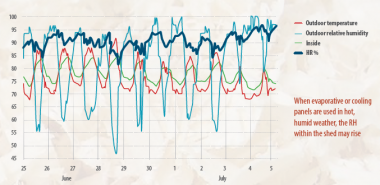

As can be seen in the chart, during the day, as the external temperature rises, humidity decreases.

At night, instead, as the external temperature decreases, relative humidity rises.

Chart 1 -Typical outdoor temperature and Relative humidity during hot weather

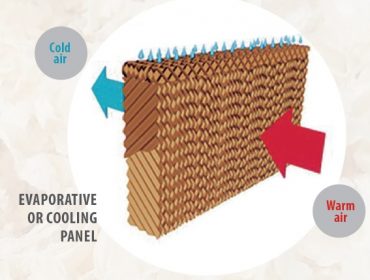

It is very important to keep in mind that the use of evaporative or cooling panels is not equal to the use of home air conditioning, since air conditioning systems lower both the temperature and the relative humidity in the air.

The more these home air conditioners are used, the lower will both temperature and humidity be in a residence.

However, evaporative or cooling panels, by definition, lower the inner temperature in the shed because the air is cooled down as it goes through the water curtain in the panel without lowering humidity as with common air conditioners.

Air cooling by evaporative panels has issues, such as an increase of humidity.

For each Fahrenheit degree the temperature goes down in the shed, the relative humidity in the air will rise by about 2.5%.

For example, when the outdoor temperature is 90°F / 32°C, and relative humidity is 55% (in hot humid weather) ordinary systems will lower the temperature of the incoming air by about 10% (80°F / 26°C), which in turn will raise the relative humidity in the air up to about 80%.

The final result is, when using evaporative or cooling panels in hot, humid weather, that relative humidity within the shed will range from about 75% to 90%, thus making it very difficult to keep the litter dry.

Chart 2. Typical conditions inside and outside the shed in hot weather

The use of evaporative or cooling panels when external temperatures are lower than 82°F /27°C can also retain or create wet litter issues.

In summer, in the Northern hemisphere the outdoor temperature and relative humidity tend to intersect at about 80°F /26°C and 80% relative humidity.

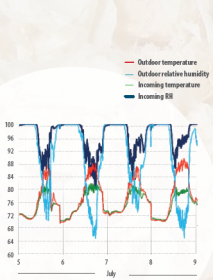

In other words, when the outdoor temperature exceeds 80°F /26°C, relative humidity will definitely be lower than 80%, and panel systems can usually be used without generating excessive humidity within the shed. Chart 3

Chart 3. Evaporative or cooling panels programmed to operate at 80°F in hot, humid weather.

However, when the outdoor temperature is under 80°F /26°C, relative humidity will tend to be greater than 80%, thus causing evaporative panels to be poorly effective due to the high relative humidity.

Under these circumstances, then, there is a inclination to force relative humidity of the incoming air up to a saturation point, making it thus impossible to keep the litter dry.

Ideally, in order to minimize damp litter problems, evaporative or cooling panels must be programmed to start as close as possible to 85°F /29.4°C, and not at 80°F /26°C.

In the example of Chart 3 the panels were programmed to operate at 80ºF/26ºC (and go off once the temperature reached 78ºF/25.5ºC).

This relatively low program setting results in the humidity in the incoming air being between 85 y 90% during the day, which is an excessively high value.

If they had been properly programmed to operate at 4ºF/28.8ºC, the actuation of the evaporative or cooling panel would have been lower, thus making it easier to control the moisture in the litter.

As can be seen in the chart, programming the coolers to operate at 80°F/26°C, results in the incoming air humidity being between 85 and 90% in the daytime.

However, if the coolers had been programmed to operate at 84°F it would have been easier to control the moisture in the litter

The faster the air, the higher the cooling effect, the lower the need to use the evaporative or cooling panel and lesser the likelihood of creating wet litter issues.

For example, if a shed with an air speed of 600 feet per minute produces a substantially higher cooling than one at 500 feet per minute, it will be much easier there to delay the use of evaporative or cooling panels, thus avoiding a negative effect on the fowl performance.

MIGRATION OF FOWL WITHIN THE SHED

Migration of the fowls within the shed is another factor contributing to create wet litter issues in the summer. Image 1.

In order to keep the litter dry, especially when the air is too humid, a high capability to circulate the air rapidly over the litter is required. The higher the moisture in the air, the greater the need to circulate the air rapidly over the bedding in order to keep it dry.

When the stocking density is too high, due to the existence of issues of migration of the fowls inside the shed, the incoming air volume in contact with the litter will be minimal, since the air flow is being obstructed by the birds themselves.

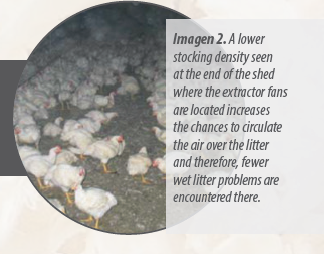

That is one of the reasons why the litter tends to be drier at the end side where extractor fans are located and the stocking density tends to be lower . Image 2

NUMBER OF EXTRACTOR FANS

There can also be problems of insufficient air circulation over the litter when using evaporative or cooling panels with less than the suitable number of fans.

Given that the air relative humidity will tend to be extremely high when evaporative panels are used, it is very important to have the maximum possible air circulation and exchange in order to secure a maximum removal of moisture in the litter.

The higher the relative humidity of the air inside a shed, the greater the need to circulate and exchange air to keep the litter dry.

This concept does not differ much from the simple example of trying to wipe off a spilled liquid with a paper towel.

The wetter the paper towel looks, the greater the need to wipe the surface with the towel to absorb the liquid; in addition, extra towels will be required to absorb all the spilled liquid.

During the last two weeks of the fattening cycle of the fowls, it will be best to use the total number of extractor fans before proceeding to the use of an evaporative or cooling panel system.

It is rarely necessary to use the total number of extractor fans to keep the younger birds comfortable, and in that case evaporative or cooling panels should run on timers.

For example, when the fowls are only two or three weeks old, panels should be operating in a manner that tempers the incoming air.

Instead of constantly using a wet water curtain to lower the shed’s temperature to 80°F/26°C or somewhat higher, with a relative humidity at over 80%, it is better to make panels run over time intervals.

In other words, they should run during less than one minute every five minutes, such that the temperature of the incoming air is lowered only to 85°F/29.4°C or a bit higher.

Restricting the use of evaporative or cooling panels will result in a humidity of about 60 to 70% inside the shed, which will make it much easier to control litter moisture.

With younger fowls, the use of cooling for less than one minute every five minutes is recommended.

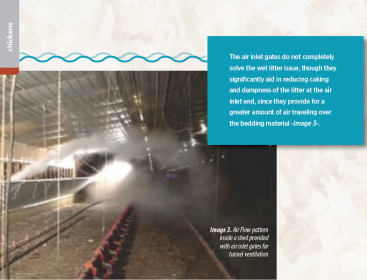

The air inlet end is the area in the shed where air circulation tends to be relatively poor, and it is consequently substantially prone to wet litter issues.

The damp caking of the litter in this area is thought to be caused by the proximity to evaporative or cooling panels and by the air holding much more moisture in this area than in other areas of the shed.

The variation of the relative humidity range throughout the shed with tunnel ventilation is normally under 10% from end to the opposite end of the shed because of the evaporative or cooling panel. It is actually the low air circulation in this area that causes the problem.

Have you ever noticed that even though litter caking and dampness tend to be greater in the air inlet area, this caking quickly disappears beyond the far end of the panel where air speed is increased?

Air speed in the area of the evaporative or cooling panel is typically lower than 300 feet per minute and it rises to 500 to 700 feet per minute once the air goes beyond the far end of the evaporative or cooling panels. As a result, the litter tends to be drier in this transition area.

Finally, the use of foggers inside the sheds in hot humid weather is a factor that significantly contributes to wet litter issues during hot seasons.

It should be noted that foggers cool down but have a poor capability to lower the temperature much inside a shed when the relative humidity is greater than 80%, which can be clearly seen in the graphs provided in this article.

Most of the water introduced into the shed by spraying or fogging systems tends to remain unevaporated, resulting in both the fowl and the litter becoming soaked.

What is even worse, humidity added to the shed by water foggers tends to get the fan paddles wet, thus increasing the likelihood of dust accumulating thereon, and reducing their potential for air circulation.

FOGGERS

Lastly, with the aforementioned issues, the cooling capacity of the poultry house is reduced. That does not mean that sprayers or foggers should never be used.

If temperature inside the shed rises to 85°F/29.4°C or more, the relative humidity in the air inside the shed will tend to be lower than 80%, and consequently a restricted use of sprayers or foggers inside the shed is recommended under these temperature conditions.

In order to be able to maintain proper conditions of the litter during hot seasons, it is critical that farmers understand the impact evaporative or cooling panels and air circulation speed can have on litter quality.

Evaporative or cooling panels can be used under high temperature conditions without resulting in excessive litter moisture.

A drier litter will provide a better environment for the fowls, with reduced caking and all of this, as a whole, will result in an easier cleaning and disinfection after the removal of the flock.